Onsite Construction Managers have a habitual saying, and it goes something like this:

- “The shingle overhang isn't straight. Get the roofer back out here.”

- “Step on the floor and it sounds hollow. Call the tile installer and get him back out here.”

- “The windows are streaked. The cleaners need to get back out here and finish the job.”

What are Construction Defect Types

Construction defects are a deficiency in the design or construction of a building or structure that results from a failure to design or construct the works accordingly.

There is a common thread in these statements, it’s the phrase, “get back out here.”

This is know as The Callback.

Within the fiercely competitive landscape of the home-building industry, where most trades contend with slender profit margins when tendering for construction projects, the spectres of inadequate structural support, construction project, and construction defect claims cast a daunting shadow. The recurrence of callbacks amplifies this challenge, denting profits significantly, especially when factoring in direct labor, payroll, vehicle expenses, and gas.

Then, there are the unseen losses, such as lost revenue opportunities and the negative good will caused by defective work / callback in the first place.

The truth is: Trades only get paid for doing the job right the first time. They have to absorb the cost of the second trip.

Implement a Quality Construction Process

How do you reduce those callbacks and reduce the overall level of construction defects? It may sound incredibly simple but take out your phone and start photographing problems (a.k.a“Hot Spots”). "Hot Spots" are points in the construction process that can be identified as continual reasons for Callbacks.

A Hot Spot photo will communicate to the crew on the jobsite, why they’re being called back. Take it a step further by photographing both the correct and incorrect way of completing a task and you can dramatically increase first time quality. Additionally, Hot Spots are extremely effective when applied to a system that’s already in place.

For instance, a swift and effective solution to reduce construction defects and address claims alleging construction defects is enhanced training. More training will tie up loose ends, shore up lacking skills, and improve design defects, ultimately helping in litigating construction defect claims. This proactive approach can even pay for itself in reduced non-billable labor costs. One approach is to pair experienced crew leaders with newcomers or even team members responsible for the initial mistake, and this can effectively resolve construction defect litigation and claims.

This doesn't always solve the consistent types of construction defects. Adding Hot Spots to the training program, and focus on those areas that are repeat offenders, and there's an increased chance that the newbie or under-performing crew member will have a better understanding of the structural expectations.

Hot Spot photos will improve poor quality workmanship, QI, and QC programs. Pictures provide clarity and a deeper understanding of what to look for. With Hot Spots, crews have an added visual tool to their checklists and inspection forms, ensuring they aren’t leaving a job-site unfinished.

Hot Spot communication doesn’t have to end when the crew leaves the job-site.

You should use the Hot Spot photos in construction meetings, Toolbox Talks and even evaluations to put the spotlight on areas where new construction defects and repeat defects are occurring.

It also provides a history that may shed some light on specific crews in the building system that need attention.

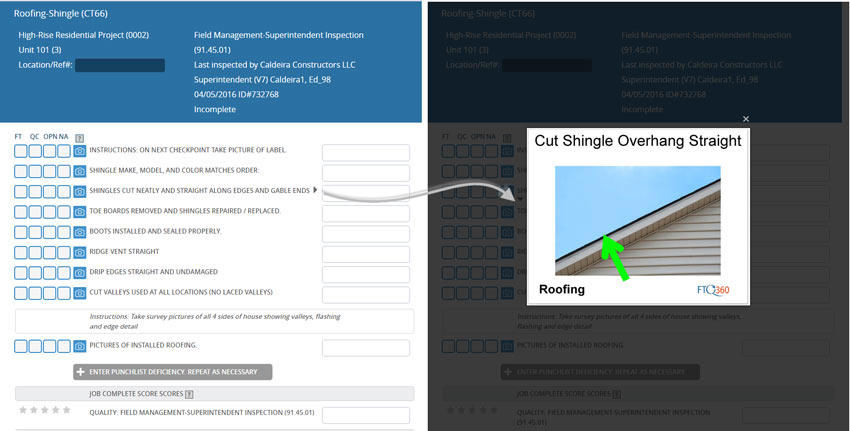

With FTQ360 software you can attach your Hot Spot training photos to your checklists and/or specific checkpoints.

For example, if you’re a general contractor and you’re getting callbacks for shingle overhang not being cut evenly, you can include a checkpoint on your roofing inspection checklist such as, "Shingles cut neatly and straight along edges and gable ends". Then attach a picture of how the correct work should look.

To enhance your construction processes, it's essential to meticulously track your Hot Spot and other checkpoints. This not only helps to minimize construction defects, especially those related to structural integrity and poor drainage but also helps in reducing overall instances of construction defects.

By adopting this proactive approach, you can better gauge the success rate of your crews in getting it right the first time versus dealing with call-backs. Moreover, it enables you to identify teams that may require additional training, ultimately leading to a significant improvement in first-time quality. Consequently, this focus on quality control will result in a substantial reduction in call-backs and a notable boost in profit margins.

So, yeah, just taking out your phone and snapping a few photos may seem like an overly simple answer to minimize defective work, but those Hot Spot photos will provide information beyond what is described in training manuals and listed on QI checklists.

Hot Spot photos, when strategically employed, prove instrumental in both minimizing construction defects and managing construction defect cases. They effectively reduce Callbacks, enhance quality, and boost profit margins.