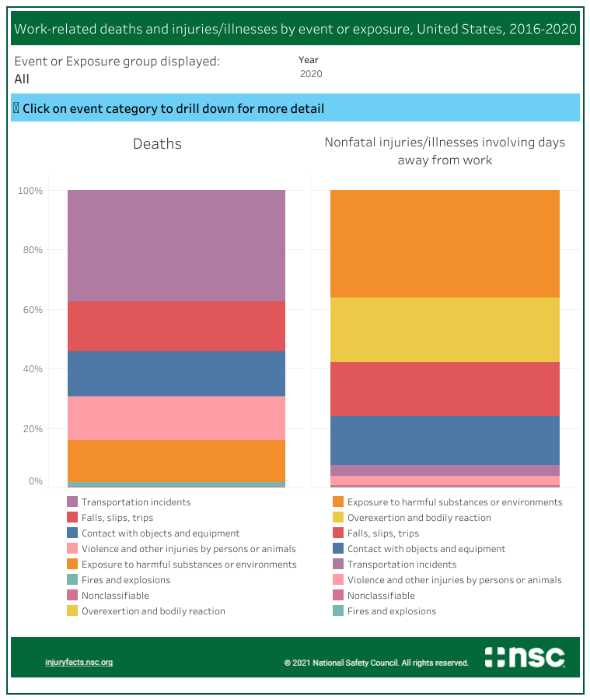

If you're like most safety managers in the energy and construction industry, you conduct safety walks on a regular basis to ensure the working environment is safe and healthy for all workers. Safety walks are an important part of any safety plan, but they can be time-consuming and fail to serve their purpose if not done correctly. According to the latest data from the National Safety Council, the top causes of work-related deaths and non-fatal injuries remain preventable causes such as transportation incidents, exposure to harmful substances or environments, and falls, trips, and slips.

(Image source: Nsc.org)

A safety walk to look-see if everything is fine is not enough on its own – it needs to be properly planned and documented. By using inspection software to collect and analyze data from safety walks, you can make the process much more efficient and repeatable.

This blog post will discuss how to use your safety software to improve your safety walks. We'll cover what you should look for in a safety walk, what an audit is, the five steps of a job hazard analysis, and how FTQ360 inspection software can help you improve safety walks.

What should I look for in a safety walk?

A safety walk involves walking around a facility or site to assess the implementation of safety policies and identify potential hazards. To streamline the process and ensure comprehensive safety management, safety management software can be utilized.

What is a Safety Audit?

A safety audit is a systematic review of an organization's safety management system. A safety audit aims to identify opportunities for improvement in the system. Safety audits can be conducted internally by the organization's staff or by an independent third party.

Check out FTQ360's Safety Program:

What are the five steps of a job hazard analysis?

A job hazard analysis (JHA) is a process used to identify and assess the risks associated with a particular job or task. The JHA process typically consists of five steps.

1) Select a job to analyze

To effectively manage safety in construction worksites, conducting a Job Safety Analysis (JSA) for each job is ideal. However, due to time constraints, it's essential to prioritize the jobs to be analyzed based on their level of importance. This process can be streamlined with the use of construction safety management software, which can assist in organizing and ranking tasks. Additionally, safety data sheets can provide critical information on potential hazards associated with specific tasks, aiding in the JSA process.

OSHA standards recommend that you consider the following factors when deciding which jobs to prioritize for a Job Hazard Analysis:

- The frequency with which the job is performed

- The number of workers exposed to the hazard

- The severity of the potential injury or illness

- The existence of any previous injuries or illnesses associated with the job

- The proximity of other potential hazards

By taking these factors into account, you can ensure that you prioritize the jobs that present the most risk and are most likely to result in an incident.

2) Identify site needs and task breakdown

The second step includes understanding the work that will be performed, the location of the work, who will be performing the work, and what tools and equipment will be used. It's also important to break down the job into its constituent steps. For example, operating a piece of machinery may involve:

- Preparation for the work, e.g., wearing PPE

- Switching on the machine

- Performing the task

- Switching off the machine

- Cleaning up

When identifying the steps involved in a job, being specific is crucial to avoid overlooking potential hazards. To further enhance safety, regular safety meetings can be held to discuss any identified hazards and incident management protocols can be put in place to swiftly respond to and address any incidents that may occur.

3) Determine risks and hazards

The third step is to identify the risks and hazards associated with each step of the job. Risks are potential accidents or incidents that could occur, while hazards are anything that has the potential to cause harm.

With tasks broken down in step 3 above, it becomes easier to identify potential hazards. For example, the job of operating a piece of machinery may involve:

Preparation for the work

- Hazard: Inadequate PPE

- Hazard: Poor training on PPE use

Switching on the machine

- Hazard: Machine malfunction

Performing the task

- Hazard: Musculoskeletal injury

- Hazard: slips, trips, and falls

4) Develop preventive controls

The fourth step is to develop preventive controls to mitigate the risks and hazards identified in the previous step. There are a variety of different types of preventive controls, including:

- Elimination: The best way to control a hazard is to eliminate it. While this may not always be possible, it should be the first option considered.

- Substitution: If elimination is impossible, the next best option is to substitute the hazard for something less harmful. For example, using a less toxic cleaning solution.

- Engineering controls: These are physical changes to the work environment that reduce or eliminate exposure to hazards. For example, installing ventilation to remove harmful fumes from the air.

- Administrative controls: Administrative controls are changes to working practices that reduce or eliminate exposure to hazards. For example, a policy that all employees take a five-minute break every hour reduces the risk of repetitive motion injuries.

- PPE: Clothing or equipment designed to protect workers from exposure to hazards.

5) Document and Share the JHA Report

The final step is to document the findings of the Job Hazard Analysis in a report. This report should be shared with all employees who perform the job and their supervisors. The report should also be kept on file in case it's needed in the future.

How Does FTQ360 Inspection Software Improve Safety Walks?

FTQ360 inspection software can help improve safety walks in a variety of ways. First, the software provides a platform for conducting daily safety audits. This allows managers to identify and address potential hazards quickly. Second, FTQ360 makes it easy to add hazard-specific checkpoints to safety walks, such as scaffolding or earthwork-specific checks relating to excavation. This helps to ensure that all potential hazards are accounted for and can be helpful when insurance companies request proof of your rigorous procedures.

FTQ360 includes a table within the daily report to record man-hour reports. This helps to monitor personnel on-site by recording the hours worked and compliance with OSHA manhour exposure reporting requirements.

The FTQ360 software is a valuable tool for reporting safety observations and assessing the severity of hazards on a scale of 1 to 10, ranging from minor to life-threatening. By incorporating FTQ360 into a broader safety management system, these observations can be effectively tracked and addressed, minimizing the risk of incidents. This system can also aid in risk management by providing valuable data on potential hazards, allowing for proactive measures to be taken to mitigate risks and increase workplace safety.

Finally, reporting and analytics features allow managers to track trends in safety walk performance. You can use this feedback to pinpoint areas where policies are not followed and more training or action is needed. Ultimately, FTQ360 inspection software helps to create a safer workplace by providing a comprehensive tool for managing safety walks.

![[FREE GUIDE] How to Quickly Improve Your Subcontractors Performance](https://no-cache.hubspot.com/cta/default/3353989/fac47599-fc2e-4c85-89b3-d0fc8a6cb984.png)