Subcontractor reliability and performance are essential to the success of General Contractors and home builders. When subcontractors underperform, it’s frustrating, time-consuming, and brings the construction contracts to a grinding halt.

Experiencing problems with subcontractor performance or their consistent presence on the job? You're not alone; these issues are quite common. It's essential to know how to monitor subcontractor performance and utilize subcontractor management software to streamline the process. In doing so, incorporating statistical quality control ensures that the evaluation process is grounded in data-driven insights, allowing for a more objective assessment of performance.

Simultaneously, integrating quality assurance measures becomes crucial to maintaining project standards and identifying areas for improvement systematically. This comprehensive approach not only addresses immediate performance concerns but also places a strong emphasis on customer satisfaction, as meeting or exceeding quality expectations is key to the overall success of your projects.

Subcontractor Management

Can the Builder help improve an underperforming subcontracting partner? Or should the Builder cut its losses at the first sign of shoddy work, and get other subcontractors?

Those answers can actually lie within a properly implemented Subcontractor Quality Control Plan.

A QC Program goes beyond the basics, offering robust solutions for monitoring subcontractor performance, contractor performance, and maintaining stringent quality and safety standards. It's a versatile tool that spans multiple projects, jobs, and areas, aligning with the effectiveness of top-tier project management software.

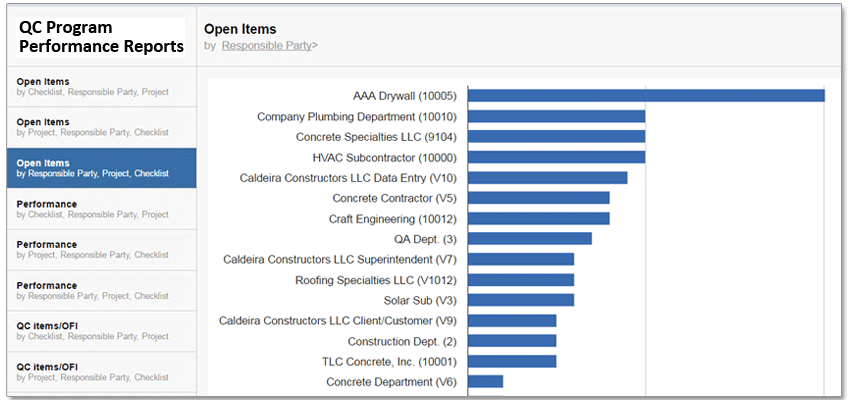

With those facts, the Builder can first understand the depth of the subcontractor performance issue and have a primary performance measure that accurately shows the work being done.

- Is it a cascading failure across all projects or is it an isolated incident?

- How long has it been occurring?

- How much scheduled time has been lost.

- What are the associated costs to your bottom line?

This data gives the Builder solid information to decide whether to replace a sub-par contractor or to talk to the company and work-through the subcontractors work.

Regardless of the decision, facts always trump conjecture. “Our Super says your crew isn’t showing-up” doesn’t carry the same weight as “Your crew has been one-to-three-days late on eighteen jobs in the southeast region for the last two weeks, and now twelve jobs are behind schedule.”

Back that up with performance graphs from the QC Program’s reporting tools, and the Subcontracting Partner has little room to contest the work performed.

However, a subcontractor who has been a good, reliable partner in the past is probably worth helping.

Identifying the root of the problem is the first step. Obviously, the Builder wants to ask why the Subcontractor isn’t completing the job or why the crew isn’t showing-up to the construction project.

But those are Generalities, and generalities are non-productive.

With the performance information mined from the QC Program, the Builder can dig deeper to find recurring issues in the subcontractor's work or common triggers.

Why didn’t the Subcontractor complete the job on lot 7 of block 9 on August 12th and was it a different reason from lot 13 of block 2 on June 29th?

How to Manage Subcontractor Performance on a Construction Project

There are many causes for a construction Subcontractor’s under performance.

Most often, material delays, manpower shortages and schedule bottlenecks, or an out of their control error will be sited as excuses in the subcontractor performance.

Sometimes the subcontractor is taking on more work than it can handle. On the surface, these conditions have solutions that can be negotiated between the project managers and the subcontractor. However, it's crucial to delve deeper into the situation and implement a structured approach to evaluate subcontractor performance. This involves conducting a thorough performance evaluation that considers business processes and quality criteria.

By systematically assessing the subcontractor's capabilities against predefined quality criteria and evaluating their alignment with established business processes, you can address challenges more effectively. This ensures that the subcontractor is equipped to handle the assigned workload, fostering a collaborative environment and optimizing overall project performance.

However, there are usually other, hidden root causes that are on the Builder’s side of the partnership. The subcontractor may not speak-up about these problems. So, the Builder needs to be prepared to ask:

- Is the job site clean and ready for the Sub to do its job?

- Does the crew or subcontractor know and understand the Builder’s performance criteria and best practices? Are those standards and best practices clear? Do they need to be established?

- Is there a language barrier preventing effective communication with the general contractor?

- Are there any interpersonal differences between a crew and a Construction Manager?

- Is the Subcontractor regularly receiving feedback (positive and negative) from the Builder?

Whether the causes lie with the Subcontractor or the Builder (and realistically they probably lie with both), an improvement plan can be put in place to close out.

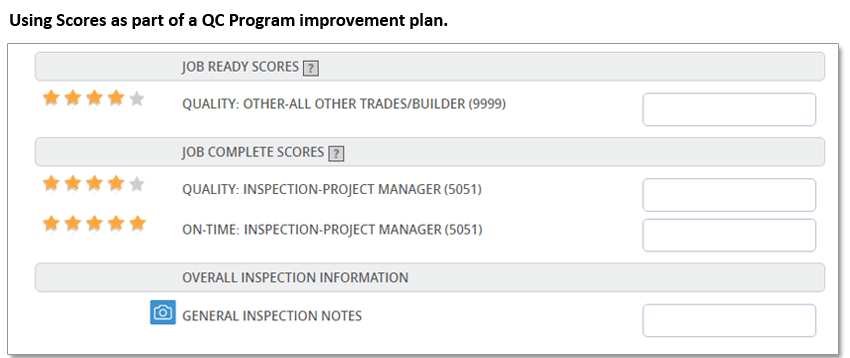

An improvement plan harmoniously aligns with the QC Program, ensuring steadfast consistency in your project schedule even when dealing with multiple subcontractors. If the Subcontractor has effective solutions in place, spanning punctual jobsite attendance to thorough end-of-day cleanup, subcontractor management software, and trending reports become essential tools. These resources empower both the Builder and the Sub to comprehensively evaluate and monitor subcontractor's performance, thus significantly impacting project outcomes.

Also, both the Construction Manager and the Subcontractor can provide notes and expectations to further explain events on the jobsite.

This can hold the Construction Manger accountable for scheduling errors and jobsite readiness and cleanliness, which can severely impede the Subcontractor’ performance.

The improvement plan should include Hot Spots, which are simply reminders with pictures.

Recurring items on a punch list, or that are generating callbacks, can become a flyer placed near the work area; or pictures on a checklist for subcontractors to use in construction projects.

It reminds the crew performing the work to double check those items. These can be written in English and Spanish and include photos – the universal language.

Finally, as the project manager, it is your duty to communicate your standards and best practices through defined scopes of work, such as key performance indicators, checklists and inspections. This process can be known as the subcontractor management process.

Maintaining high safety standards among your team members and subcontractors will save you lots of time and money.

A checklist is simply the required steps within a repetitive task. Checklists provide organization and process standardization.

They also save time, reduce errors, and ensure quality work. If this is lacking in the Subcontracting Partner’s company, it can be a game changer.

The structure of standardized checklists will help the Sub keep-up with a growing backlog of jobs and eliminate callbacks. It’s a win-win for both the Subcontracting Partner and the Builder in project management.

Implementing these tips to your own workers will allow you to build a subcontractor management best practice plan that improves product quality.

For a successful Builder-Subcontractor Partnership, implementation of standardization measures and fostering ongoing feedback and discussion about jobsite issues in an open and supportive environment are crucial. Two-way communication is essential, and the QC Program acts as the platform enabling this vital exchange. In maintaining quality requirements and adhering to safety regulations, the QC Program plays a pivotal role. This structured program establishes a systematic approach to quality and safety, contributing to the competitive advantage of the collaboration. Integration of quality requirements and safety regulations enhances the partnership's ability to meet and exceed industry standards, ensuring long-term success in the construction sector.