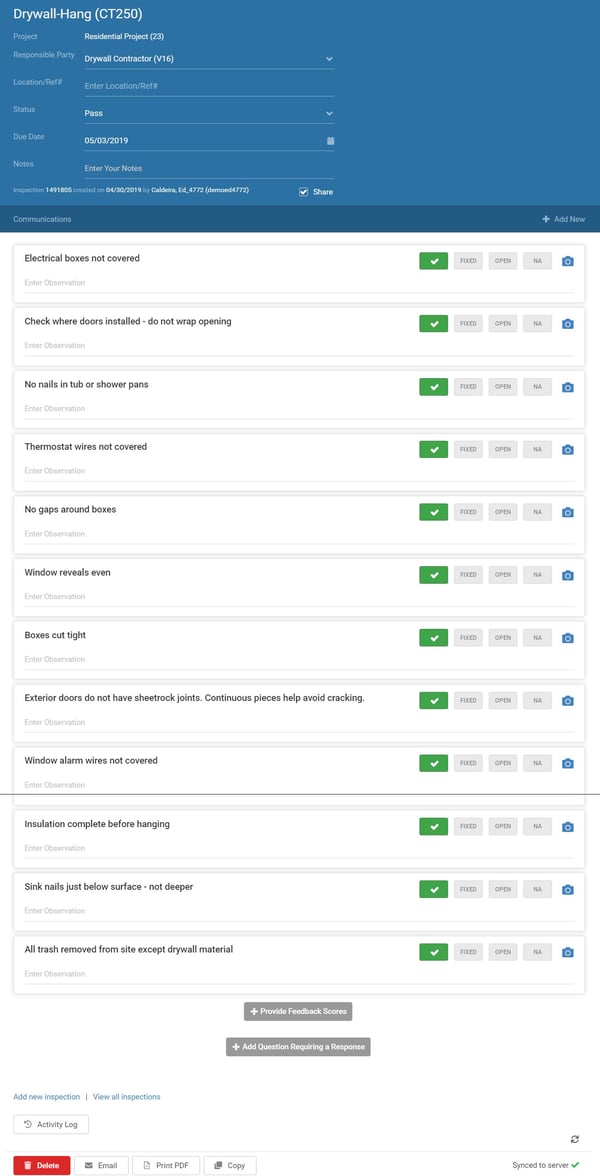

Many causes of home warranty issues cannot be seen during the closing process because they are hidden behind drywall. A pre-drywall inspection (example) is the last opportunity to catch deficiencies before they cause problems months in the future.

Use this comprehensive pre drywall inspection checklist to ensure your build is on track and compliant with building codes, energy efficiency standards, and quality expectations.Why a Pre Drywall Inspection Matters

A pre drywall inspection ensures everything inside your walls is correctly installed, code-compliant, and defect-free before it gets sealed up. Inspections at this stage typically cover:- Structural framing

- HVAC system placement

- Electrical wiring and outlet box positioning

- Plumbing lines and pressure tests

- Fire blocking and safety features

- Insulation preparation

Missed defects at this point can lead to costly rework, failed inspections, delays, or unhappy homeowners.

Pre Drywall Inspection Checklist

Below is a trade-by-trade checklist to guide your inspection. Use it in the field or as part of your quality management system.

Framing

✔ All framing is plumb, level, and square✔ Nail plates are installed over vulnerable plumbing or wires

✔ Fire blocking is present where required

✔ Shear walls and headers are correctly installed and secured

✔ Stud spacing and alignment meet code and plan specs

Electrical

✔ Electrical rough-in completed

✔ Wires are secured and not kinked or pinched

✔ Outlet, switch, and fixture boxes are flush with framing

✔ Smoke detectors and GFCI/AFCI devices are installed per plan

✔ Panel is installed and labeled correctly

Plumbing

✔ Supply lines are pressure-tested and leak-free

✔ Drain and vent lines are sloped correctly and supported

✔ Water heater and main shut-off locations are accessible

✔ Tub and shower units are level and secured

✔ Nail plates protect vulnerable piping

HVAC

✔ Ducts are sealed and properly routed

✔ Returns and supplies are placed as per HVAC design

✔ Bathroom/kitchen exhausts vent outdoors

✔ Thermostat wiring is installed and accessible

✔ HVAC equipment properly supported

Fire Safety & Energy Code

✔ Fire blocking installed at vertical/horizontal breaks✔ Draft-stopping around chases and penetrations

✔ Penetrations sealed with fire-rated caulk or foam

✔ Insulation baffles and air barriers in place (if applicable)

Windows, Doors, and Exterior Penetrations

✔ Windows and doors properly flashed and sealed

✔ No gaps or daylight visible around frames

✔ Exterior penetrations (pipes, vents) sealed

✔ Sill plates caulked or gasketed for air sealing

Pro Tip: Use a Digital Checklist for Accuracy and Accountability

Paper checklists are easy to overlook. Using a digital inspection platform like FTQ360 helps ensure inspections are complete, photos are captured, and issues are resolved before drywall is installed. Teams can track deficiencies in real-time and improve accountability.

See our collection of construction checklists for Drywalls and more here

Final Inspection Notes

Before signing off:

✔ Confirm all trade inspections are passed

✔ Take photographs of each wall for documentation

✔ Ensure all punch list items are resolved

✔ Review the checklist with your team and sign off

A solid pre drywall inspection checklist is your defense against callbacks, rework, and warranty claims. Don’t skip it and use it to build better homes, faster.

Need Help Automating Your Inspections?

If you’re a home builder or quality manager looking to streamline your inspections and track results in real time, FTQ360 can help. Create custom checklists, assign tasks to trades, and document every step — all in one platform.

Learn more about FTQ360 Pre Drywall Inspection Tools

Frequently Asked Questions About Pre Drywall Inspections

What is a pre drywall inspection?

A pre drywall inspection is a critical quality control step during the home construction process. It occurs after framing, plumbing, electrical, HVAC, and other systems are installed but before insulation and drywall are added. The purpose is to verify that all components inside the walls are properly installed, up to code, and free of defects before they’re sealed in.

What should be on a pre drywall inspection checklist?

A comprehensive pre drywall inspection checklist should include items from all major trades, such as:

- Framing alignment and fire blocking

- Electrical wiring, boxes, and panel setup

- Plumbing lines, venting, and pressure tests

- HVAC duct routing and sealing

- Window and door installation

- Fire safety and air sealing

- Exterior penetrations and waterproofing

Each item should be visually inspected and documented to ensure compliance and catch potential issues early.

When should a pre drywall inspection be done?

A pre drywall inspection should be conducted after rough-ins are completed (framing, plumbing, HVAC, and electrical), but before insulation and drywall are installed. This timing allows access to all wall cavities, systems, and structural components for a thorough visual and documented inspection.

Who should perform a pre drywall inspection?

- A pre drywall inspection is typically performed by:

- Local building inspectors (as part of required code compliance)

- The general contractor or builder

- A third-party home inspector (often hired by the buyer)

- A quality assurance team, especially in production or custom homebuilding

Some builders also use construction inspection software to standardize and document inspections digitally for better accuracy and accountability.