First-time quality (FTQ), the idea that a project should be done right the first time without rework or replacement, should be applied in all parts of an electrical infrastructure project.

How can power delivery workers achieve first-time quality? By creating a solid inspection test plan (ITP) in the planning stages, an inspection checklist to ensure nothing gets overlooked, and a solid inspection process criteria for each project to work.

Below, we examine how to create, use, and manage ITPs for electrical infrastructure projects.

What Is an ITP?

An inspection and test plan is a document detailing how you will inspect your electrical works' progress to ensure that it complies with the design requirements throughout the construction period. The ITP is part and parcel of the project's quality management system and contains all the necessary details to address all the risks. It is important to note that the words "inspection" and "test" can be misleading and suggest an activity conducted on a complete project. On the contrary, an ITP is a comprehensive assurance plan and includes all activities:

- That will be undertaken to ensure the electrical infrastructure complies with design requirements and regulatory demands

- That must be completed to demonstrate compliance, for example, third-party inspections and tests

Historically, inspections were conducted in a way that wouldn't completely ensure first time quality. However, now, with a quality management system that adheres to your inspection criteria, the likelihood of missing key issues is very low.

Why Create and Use an ITP?

An inspection and test plan for the construction industry, is a proactive quality control tool to help the successful completion of the electrical infrastructure project. There are two main reasons it is critical to electrical infrastructure projects:

- It is an opportunity to identify the project requirements and prevent errors, omissions, and defects that can lead to delays, cost overruns, and reputational damage

- It helps a quality manager come up with a strategy to test and inspect the electrical works and achieve the following:

- Prevent problems well before commissioning stage of the project

- Demonstrate compliance to all stakeholders

- Timely detection of problems and an opportunity to take corrective action

- Engineers can use it as a to-do list for the inspections and tests they must complete.

The time and effort spent preparing an inspection and test plan is justified by the savings made in time and money and protecting the contractor's reputation.

How to Develop an ITP

An ITP need not be a complicated document. To someone who has never created one before, it may seem like a daunting task. However, when done correctly, it is a straightforward, practical, and systematic process.

When developing an ITP, you must keep the following three issues at the top of your mind:

- How will you be confident that the electrical works are compliant?

- What are the client's design requirements?

- How can you demonstrate compliance to other stakeholders and give them the confidence that the electrical infrastructure works are compliant with all requirements?

Having a continual focus on these questions, we suggest the following 5-step approach to create an inspection and test plan:

- Determine the scope of the ITP; for example, pre-construction, material conformity, off-site manufacture, site construction, testing and commissioning, and post-construction

- Obtain the project specifications, drawings, and all other relevant documents

- Methodically read through the documents in Step 2 and extract all the items and definable features of work that need to be listed as activities on the inspection and test plan.

- For each of the items in Step 3, state:

- The compliance requirement, identifying the specification section when applicable.

- Detail the specific inspections and tests that will be conducted

- How compliance will be documented. The evidence of compliance – in most cases, this an inspection report or a test report.

- The team member that is responsible for closing out the requirement

Step 5 above is usually created in a spreadsheet document and split into columns with each column dedicated to the items "a" to "e." The sample below is illustrative:

Who Should Develop an ITP?

The norm is that the person tasked with developing the ITP has the knowledge and experience of creating ITPs. Alternatively, someone with the relevant technical expertise may enlist a project engineer or quality manager to create the ITP.

On large projects, the best way to develop an ITP is a collaborative approach. For example, hold a workshop that brings together all quality assurance stakeholders to contribute based on their knowledge and experience.

The Detail in an ITP

The detail in an inspection and test plan is a judgment call by the stakeholders and dependent on several factors, including the activities that need to be conducted and the risk involved. The only caveat is to ensure that all items relevant to the project scope are included to ensure the ITP is an effective quality assurance plan.

The Role of Checklists in an ITP

The ITP uses checklists to simplify the process of what to check for each ITP line item. Each checklist contains a series of checkpoints that sets the agenda for necessary items to verify and test data to measure in order to pass.

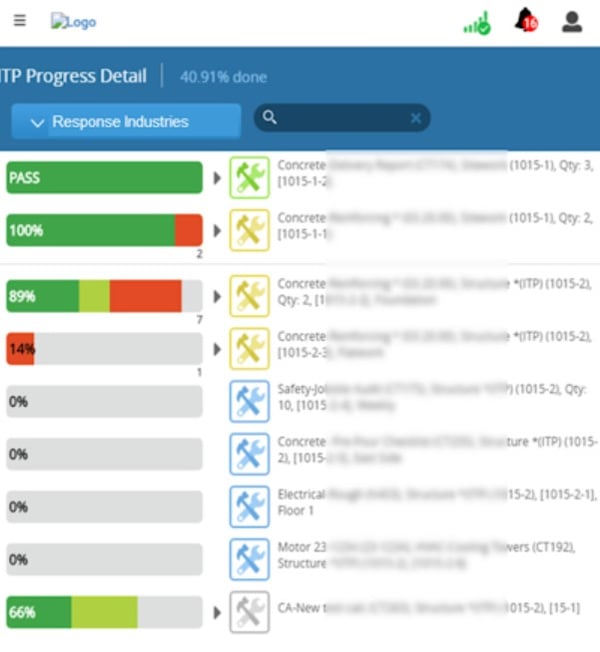

Managing ITPs during the Project

As inspections and tests are completed, post the report to the ITP. You’ll quickly see what is completed, what is in process, and what may have been missed.

A Better Way to Create, Use and Manage ITPs

The traditional approach is to create, use, and manage ITPs with spreadsheets. Spreadsheets are useful until they aren't. For large projects, the sheer scope of inspections and testing that needs to be carried out during the project's duration make spreadsheets a clunky and cumbersome method.

Also, spreadsheets are difficult to share with a large project team. When it's a single contractor working on a small domestic electrical works project, a spreadsheet does just fine. But what happens at a large electrical infrastructure project where a single master spreadsheet needs to be shared and updated across an entire quality assurance team? It quickly becomes a logistical nightmare and is always out of date.

There is also no clear indication of who is working on what at a particular time. Unless everyone has been trained to enter meticulous notes and follow a strict documentation process, it can be difficult to tell who conducted an inspection/test and when it was done.

Shared spreadsheets can also create the problem of multiple versions of the truth. Every time a change is made, the user has to sync the changes to ensure the master spreadsheet is updated. Forgetting to do so or encountering a connection error can lead to several versions of the spreadsheet.

There is also the fact that spreadsheets are prone to errors. According to a study by Ray Panko, a University of Hawaii professor, almost 90% of spreadsheets contain errors. So, isn't it ironic that a process that seeks to eliminate errors would be managed using spreadsheets?

Reporting is also painful. Every so often, quality assurance managers must extract the data from spreadsheets and write a report. This is a time-consuming exercise and not for the faint-hearted.

These are just some of the drawbacks of spreadsheets. A better way to create, use, and manage inspection and test plans is with specialized software such as the FTQ360 Power Delivery Quality and Safety Platform.

Back to You

When you're serious about first-time quality in your electrical infrastructure works, upfront planning becomes essential. Whether you want to learn more of how to conduct a visual inspection or how to establish safety programs, we've got you covered.

With FTQ360, inspection and test plans are built right into the process. Get in touch for more information or to book a demo.