Quality assurance (QA) and quality control (QC) are critical components of any construction project. QAQC plans help ensure that the finished product meets all requirements and that any defects are identified and corrected before they cause serious problems.

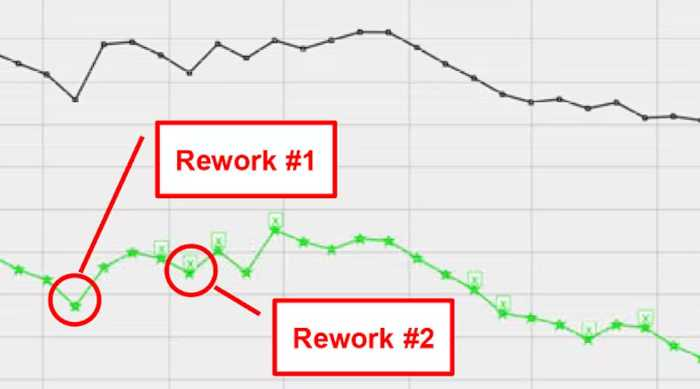

Numerous studies have illustrated the benefits of a construction quality control plan. For example, some recent studies have shown that 4-6% of total project costs can be attributed to rework and that construction rework activities can contribute directly to up to 300% in productivity losses.

(Image source: ecmweb.com)

A construction quality control plan can save both time and money by identifying and addressing potential problems before they arise. In construction—especially with specialty trades or complex technical work—there’s no substitute for a well-designed, comprehensive quality control plan.

What Is a Construction Quality Control Plan (QAQC Plan)?

Control in construction ensures that the final product meets the client’s needs while staying within the agreed budget and schedule. The three key aspects of control are quality, time, and cost. To meet these goals, it's essential to implement a strong quality management system and a thorough quality assurance process. These help ensure that the finished work meets all specified requirements and standards, while staying on time and within budget.

Quality control (QC) in construction involves monitoring and regulating the project to ensure the final result meets the client’s expectations. A construction quality control plan is a document created by the quality control manager that outlines how quality will be managed throughout the project. This plan includes the project’s quality goals, along with the methods and procedures used to achieve them.

Key Benefits of a QAQC Plan

A well-crafted quality control plan is essential for ensuring that a project meets all applicable standards and regulations. By extension, a quality assurance/quality control (QAQC) plan helps to ensure that the project is delivered on time, on budget, and with no surprises.

Here are some of the critical benefits of quality assurance/quality control plans:

- A good control plan extends the quality program deeper into specialty trade compliance, technical work, or project startup and commissioning. This helps the quality control manager ensure quality and process efficiency across the entire project, and that all aspects of the project meet the necessary standards and customer requirements.

- Having a single control plan that outlines all control methods, quality planning, and orchestrates all engineering inspections, performance tests, and checklists helps to streamline production processes and makes it easier to track progress and identify potential areas of improvement. This is all made significantly easier when the control plan resides on a mobile- and tablet-friendly digital platform, which the quality manager can take on-site to record quality control testing results in real-time.

- Finally, a quality assurance/quality control plan helps to create a culture of quality within the organization that can be applied to future projects. By instilling a commitment to quality at all levels of the organization, QA/QC plans help to ensure that projects are delivered according to the highest standards.

Functional Goals of a QA/QC Plan

The primary goals of a QAQC plan are to ensure that the finished project meets all customer requirements specified in the contract documents and to avoid potential problems that could result in delays or cost overruns.

To achieve these goals, a quality assurance/quality control plan should include digitizing all inspection and test data, storing it in a database for real-time visibility and analytics, and eliminating non-productive administrative tasks related to transcribing data into reports, writing emails, conducting deficiency reporting, tracking, and documenting corrections.

Implementing a QA/QC Plan for Construction

The Quality Assurance/Quality Control (QAQC) plan should be developed during the planning phase and updated as needed throughout the construction process. This plan should include detailed quality control procedures, a system for measuring key aspects of the project, documentation of all measurements taken, and analysis of the resulting data. A well-designed QA plan is essential for maintaining high standards and ensuring the project meets all specified requirements and quality benchmarks. It also relies on the expertise of the construction team to stay aligned with these goals.

Using a digital inspection tool can greatly enhance the QAQC process. It speeds up inspections, improves accuracy, and ensures consistent data collection. By digitizing inspections, all relevant information is captured in real time, helping ensure the QAQC plan is properly followed throughout the project. This also makes it easier to demonstrate compliance during quality audits.

Elements of a QA/QC Plan for a Construction Project

There are six essential components of a QAQC plan:

- Quality policy and objectives: The quality policy is a statement from management that defines the quality objectives for the project. The quality objectives should be specific, measurable, achievable, relevant, and time-bound (SMART).

- Documented Standards and Specifications: All quality standards and specifications for the project should be documented in the QA/QC plan. These may include international standards such as ISO 9000 or national standards such as Safety Schemes in Procurement (SSIP).

- Formal Qualifications of Employees, Subcontractors, and Suppliers: The QAQC plan should include a list of all employees, subcontractors, and suppliers who will be involved in the project. For each individual, the plan should specify their qualifications and experience. The QAQC plan should include how employees, subcontractors, and suppliers are qualified to work on the project. This may mean soliciting specific certifications or degrees, or demonstrating that they have a certain amount of experience in the field.

- Quality Control and Assurance Procedures: The QAQC plan should describe the procedures used to detect quality issues and control quality throughout the project. These procedures may include quality audits, inspections, listing all performance tests conducted, and reviews.

- Inspection and Test Plan: The inspection and test plan is a critical part of the QA/QC plan. It should specify a step by step process – or include a process flow diagram – detailing when and how inspections and tests will be conducted, and what criteria will be used to accept or reject work. It should also define the tools used to conduct inspections, audits, and testing.

- Control and Prevention of Non-conformances: The QAQC plan should also include procedures or process flow diagram for preventing and correcting quality problems. These may consist of rework, repair, or replacement of defective work. The plan should also define how nonconformances will be documented and tracked.

FTQ360 QAQC Planning Software Features and Functions

FTQ360 is a process-oriented quality management software for streamlining quality assurance and quality control planning in construction. The software provides a centralized quality control system you can use to plan and manage quality assurance surveillance, inspections, and tests.

With its many features and functions, FTQ360 is a hugely valuable, efficient, and user-friendly solution for conducting QA/QC processes.

Three key features:

- Turnkey QAQC plan templates for general construction, homebuilding, and modular construction projects.

- Forward planning of Project-specific inspections, tests, and QC activities.

- ITP management dashboards track plan execution and highlight deviations from the plan.

If you're looking for quality software to help with your QAQC planning, look no further than FTQ360. Contact us today to learn more about our quality management software or book a demo.

![[FREE EBOOK] Your Complete Guide to Achieving First Time Quality](https://no-cache.hubspot.com/cta/default/3353989/8c80b65c-b362-4e46-af1b-0ecf2d1581db.png)