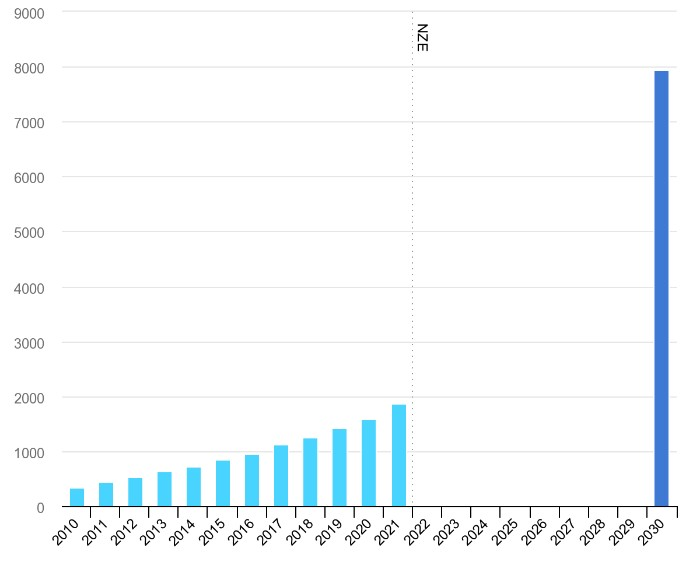

Wind farm construction projects have grown exponentially in recent years in response to the climate crisis. According to the latest statistics by the International Energy Agency (IEA), wind electricity generation increased by a record 273 TWh (up 17%) in 2021.

In the same year, renewable energy witnessed a striking 55% growth rate compared to 2020 – the highest increase among all renewables – due to an exponential surge of wind capacity expansions. 2020 alone saw 113 GW added compared with 59 GW in 2019, thus propelling this unprecedented advancement in sustainable power sources.

To meet net-zero emission (NZE) requirements by 2050, there will be increased investments in large-scale wind power farms.

(Image source: iea.org)

These massive wind farms are complex construction projects costing millions or even billions of dollars to develop.![[FREE EBOOK] Five Core Digital QAQC Functions for Successful Energy Projects](https://no-cache.hubspot.com/cta/default/3353989/2330d6b5-fdab-4c20-b603-b943735f1d7a.png)

QAQC in Wind Farm Construction Projects

With the growing scale of wind energy projects comes the need for stringent quality assurance (QA) and quality control (QC) procedures. Quality is essential to ensure the structural integrity, safety and performance of onshore and offshore wind projects, from turbine blades to transmission lines. For the industry to continue providing clean, renewable energy from wind farms, project managers must implement effective QAQC programs.

Why Is QAQC Important for Wind Energy Projects?

Quality Assurance and Quality Control (QAQC) are vitally important for wind energy projects, as they ensure the project is built to last and meets all relevant standards.

Safety is an integral part of QAQC, ensuring no one gets injured on the job site. This is particularly important for a renewable energy project, where worker safety is paramount. Upper-level management must support the safety program to guarantee “safety first.” Further, contractors must be certified with adequate training and understand the job hazards associated with working on the project.

It is also essential to adhere to various engineering standards such as IEEE, ANSI, UL, ASTM and ASCE when constructing a wind project.

In addition, permit compliance needs to be followed to comply with federal regulations and zoning requirements. Some permits may be required where the project falls within the ambit of the following federal organizations:

With proper QAQC measures in place, wind energy projects can ensure safe and long-lasting functionality. This is especially crucial for an offshore installation, which can face harsh weather conditions. Additionally, adherence to industry standards can help ensure seamless integration with the national grid. Stay up-to-date with the latest industry news on QAQC measures to optimize your wind energy project's performance.

There is also a raft of zoning standards and practices such as the Wind Energy and Wind Park Siting and Zoning Best Practices and Guidance for States and Standardization of Permitting and Zoning (for Distributed Wind). The former is a report from the National Association of Regulatory Utility Commissioners and provides guidelines for managing the siting and zoning processes and applying siting and zoning principles to wind energy decision making, while the latter is a permitting toolkit based on industry best practices and positive examples already in place in the US Northwest region.

What to Expect from Large Wind Farm Projects

Quality control is crucial at every stage of a renewable energy project, from the manufacturing of individual components to installation at the project site. This is especially important for large wind farms with high combined capacity, where even minor defects can have significant impacts on performance and safety.

Each component requires inspection at different stages of the construction process, starting with the pre-construction phase through to completion.

Pre-construction inspections include evaluating site conditions, confirming design plans are up to code, and verifying that the materials being used meet quality standards.

During construction, onsite periodic inspections must be conducted to verify safety protocols are implemented correctly and that all regulatory requirements are met.

Additionally, post-construction inspections should be performed to confirm quality assurance standards were met and that all components are functioning properly for the project's life cycle.

Inspections play a crucial role in ensuring the successful construction, maintenance, and operation of a wind farm project. From assessing civil engineering aspects during the construction phase to monitoring offshore wind turbines throughout their commercial operation, inspections are necessary for identifying potential issues and ensuring the safe and efficient operation of the project over its lifespan.

Types of Inspections Performed During QAQC Processes

Wind farm project inspections are an integral part of the wind energy process, providing oversight of each stage from fabrication to operation. These inspections involve a review of a wide range of elements, including manufacturing of components, storage and transport of equipment, assembly of assets, assessing asset performance and condition during operation, planning and evaluating maintenance tasks, investigating damage incidents, and even extending the lifetime of a wind farm.

Also, inspections monitor project milestones that trigger financial rewards to stakeholders, such as completing operability tests or taking wind measurements.

Effective QAQC inspections ensure that wind energy projects remain reliable and cost-effective throughout their lifecycle.

How FTQ360 Quality Management Software Improves Wind Project QAQC

FTQ360 is a quality management software that provides a comprehensive QAQC solution for wind projects. Our software simplifies the process of tracking, organizing and analyzing data from various types of inspections. It also helps organizations comply with regulatory standards by providing an intuitive platform for promptly completing inspection reports.

The software includes features such as mobile and web inspection forms, automated audit trails, real-time project dashboards and secure data storage. It also allows users to easily access wind project records to track performance over time, helping to identify areas of improvement and ensure that the quality assurance standards of the project have been met.

FTQ360 is an invaluable tool for improving accuracy and efficiency when managing quality control and quality assurance processes for wind energy projects.

By using FTQ360's quality management software, wind farm projects can benefit from improved visibility into compliance requirements and inspections which help reduce risks associated with non-compliance.

For more information on how FTQ360 can help you set up and manage and QAQC program for wind farm construction, sign up for a free demo.

Frequently Asked Questions About Wind Farm Construction Projects

1. What is involved in a wind farm construction project?

A wind farm construction project typically includes several key phases: site assessment, permitting, infrastructure development, wind turbine installation, electrical system integration, and final commissioning. Each stage requires careful planning, compliance, and quality control to ensure efficiency and safety.

2. Why is QAQC important in wind farm construction projects?

QAQC (Quality Assurance and Quality Control) is critical in wind farm construction projects to ensure that components are installed correctly, meet engineering specifications, and comply with regulatory standards. Strong QAQC practices reduce costly rework, improve reliability, and support long-term energy production performance.

3. What are common quality issues in wind farm construction projects?

Common QAQC challenges include improper foundation alignment, inadequate bolt torqueing, incomplete documentation, and inconsistent inspection procedures. These issues can lead to safety risks and operational inefficiencies if not addressed proactively.

4. How can construction teams improve quality in wind farm projects?

To improve quality, teams should implement standardized QAQC checklists, conduct regular inspections, use real-time reporting tools, and provide comprehensive training. Digital quality management platforms also streamline compliance tracking and issue resolution.

5. What standards and regulations apply to wind farm construction QAQC?

Wind farm construction projects are governed by standards such as IEC 61400 (wind turbine standards), ISO 9001 (quality management), and national building codes. QAQC protocols must align with these frameworks to ensure regulatory compliance and safe operation.