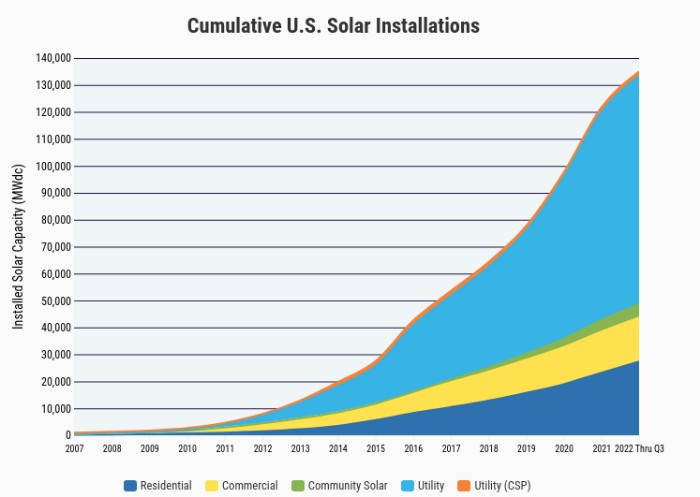

In recent years, the solar power industry globally has grown exponentially. The USA is one of the leading countries in solar power production. From 0.34 gigawatts (GW) in 2008, U.S. solar power capacity has ballooned to an estimated 97.2 GW today.

(Image source: seia.org)

The story is the same worldwide, with global installed solar generation capacity hitting around 1.1 TW (Terawatt) by the end of 2022. Most of this growth came from utility-scale Photovoltaic (PV) plants (>1 MW), with residential and commercial PV systems making up a smaller portion of total installations.

Utility-scale PV plants require a robust quality management system to ensure that their development, construction, and operation are carried out to the highest standards. Quality control activities play a critical role in this process, helping to identify and rectify any issues that may arise during the plant's lifecycle. These plants are typically owned by electric utilities or independent power producers and sell electricity to the grid under long-term contracts. They can span several MWs in size and cost hundreds of millions of dollars to develop.

Solar Energy Project Quality Assurance

With the growing scale of solar energy projects comes an increased need to ensure that all work-product created adheres to the highest quality standards. To ensure investor trust and the robustness of solar system projects in the long run, it is critical that best practices for PV system installation and operation be established.

When constructing large-scale solar energy projects, quality control(QC) is essential. This includes testing materials used, inspecting physical components such as photovoltaic cells, cables and inverters, and evaluating the overall design's effectiveness. Quality assurance (QA) then follows to verify that all aspects meet the previously specified standards before delivery.

A well-run QAQC program, which includes quality criteria that align with customer expectations, improves the quality of a solar energy project, reduces rework costs, and decreases the likelihood of warranty claims. Further, an effective QAQC program can help prevent safety hazards for the solar industry. For these reasons, it is critical that solar project managers clearly understand how to set up a QAQC program that meets the project's quality criteria and customer expectations before starting work on a utility-scale solar project.

Why is QA/QC Important for Solar Energy Projects?

There are several reasons why QA/QC is important for solar energy projects:

-

To ensure that PV systems are designed and built to meet performance expectations

-

To verify that PV systems are installed according to industry best practices

-

To confirm that PV systems are commissioned correctly and are operating as expected

-

To provide documentation that can be used to troubleshoot problems or resolve warranty claims

-

To improve investor confidence in the long-term performance of solar energy projects

-

To reduce the risk of costly rework or litigation down the road

-

And perhaps most importantly, to help ensure that solar projects deliver clean, safe, reliable, and renewable energy for years to come

What to Expect from Large Solar Projects

Due to the nature of solar panels, everything must be made to exact specifications, or else issues may arise which could negatively affect the finished product. Common problems which can arise in solar power projects include:

-

Broken or chipped cells

-

Bubbles on panel

-

Damage to panel

-

Foreign materials within cell

-

Incorrect cable length

-

Incorrect cell color

-

Insulation resistance

-

Micro-fractures on solar cell

-

Poor battery performance

-

Scratches on glass

-

Solar cell string alignment

-

Traces of glue on the junction box

-

Water ingress

-

Wrong dimensions

Types of Inspections Performed During QAQC Processes

Typically three different types of inspections occur during QAQC processes for solar power projects: pre-production, post-production, and audit & production monitoring.

Pre-Production Inspections

The pre-production inspection happens before any construction begins and focuses on approving project plans – ensuring that specific materials will be available at each step and building codes are met across multiple jurisdictions.

Pre-production inspections are a crucial component of a comprehensive quality plan for PV modules and components. These inspections help ensure that the products meet both technical specifications and customer requirements, and that manufacturing processes comply with international standards. Conducted before the products are shipped from the factory, inspections can identify potential quality issues early on, minimizing the risk of costly rework or warranty claims. Inspections can be conducted by independent third-party inspectors or in-house factory staff, depending on the manufacturer's preference and quality plan.

Post-Production Inspections

The post-production inspection occurs when all constructions have been completed and assess whether anything needs to be adjusted before final delivery.

Post-production audits are conducted after installed PV systems are but before they are commissioned. These audits can verify that installation work was performed according to industry best practices, confirm that all system components have been installed correctly, and identify potential safety hazards. Post-production audits are typically conducted by independent third-party auditors but can also be conducted by in-house staff.

Audit and Production Monitoring

Finally, audit and production monitoring takes place throughout construction so adjustments can be made immediately if any discrepancies are found. This helps ensure that all safety regulations are being properly followed and progress being tracked against timelines set during planning stages.

Production monitoring is a continuous process that begins after a PV system has been commissioned and continues throughout its lifetime. Production monitoring can involve regular on-site visits to check for proper operation of equipment, monthly or quarterly reports from monitoring software platforms, or both.

How FTQ360 Improves Solar Project QAQC

FTQ360 is a leading provider of quality management software for solar projects. The software provides an easy-to-use platform for managing project quality and safety, as well as subcontractor and supplier performance. The system includes features such as real-time reporting, inspection checklists, and automated punch lists. This allows quality managers to quickly identify any issues with the project and take corrective action before they become major problems.

The software also helps to improve communication between the quality manager and other team members involved in the project. With real-time reporting, everyone can stay up to date on the progress of the project and any potential issues that may arise. This helps to ensure that all stakeholders are informed about what’s happening on the project at all times, which can help prevent costly delays or mistakes.

Solar PV systems have a long service life, so it’s important that they are built with high levels of quality control from start to finish. FTQ360’s software makes it easy for quality managers to monitor every aspect of the project, ensuring that it meets all safety and quality standards throughout the construction process.

In addition to providing a comprehensive platform for managing solar projects, FTQ360 also offers helpful tips for improving your QA/QC control processes. These include:

-

Creating detailed inspection checklists

-

Using mobile devices for inspections

-

Automating punch list items whenever possible.

By following these tips, you can ensure that your solar projects are completed with maximum efficiency and accuracy.

For more information on how FTQ360 can help you meet your QAQC goals, sign up for a free demo.