Quality Assurance and Quality Control (QAQC) are vital components in the oil and gas construction industry. They ensure that projects adhere to industry standards, prevent accidents, and minimize environmental impact. Human errors have been the cause of innumerable calamitous events in oil well and gas extraction. According to one study published by the International Journal of Occupational Safety and Ergonomics, human factors are the most common cause of catastrophic accidents in the oil and gas industry.

Quality Assurance and Quality Control (QAQC) are vital components in the oil and gas construction industry. They ensure that projects adhere to industry standards, prevent accidents, and minimize environmental impact. Human errors have been the cause of innumerable calamitous events in oil well and gas extraction. According to one study published by the International Journal of Occupational Safety and Ergonomics, human factors are the most common cause of catastrophic accidents in the oil and gas industry.

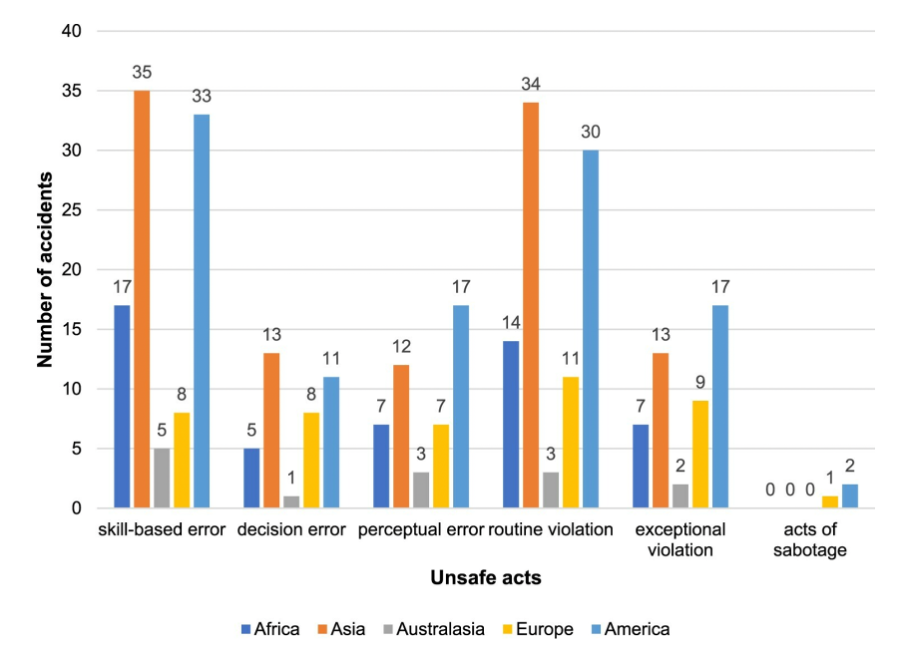

(Image source: tandfonline.com)

One would imagine that the oil and gas industry would have learned the value of QAQC from major catastrophes such as BP’s Deepwater Horizon rig explosion and the Piper Alpha disaster. Unfortunately, however, not every organization has implemented proper QAQC protocols, which has resulted in further accidents – such as the explosion of a natural gas pipeline in Beaver County, Pennsylvania, in September 2018, and the explosion of an oil pipeline in West Texas in August 2019.

These are just a few examples of accidents that have occurred due to poor quality assurance and quality control in the oil and gas industry. It’s crucial, therefore, for companies to ensure that they have proper safety procedures in place to prevent such incidents from occurring.

Below, we explore the best practices and key benefits of implementing an effective QAQC system in oil and gas construction projects, helping companies maximize their return on investment, minimize accidents, and maintain a strong reputation within the industry.

Understanding QAQC in Oil and Gas Construction

QAQC comprises two distinct but interrelated processes:

-

Quality Assurance (QA) is a proactive approach that focuses on preventing defects and non-conformances by implementing standard operating procedures, project management techniques, and regular performance evaluations.

-

Quality Control (QC) is a reactive approach that involves the inspection and testing of materials, components and finished products to ensure they meet specified requirements.

Together, these processes create a robust QAQC system that ensures the quality, safety, and efficiency of oil and gas construction projects.

Best Practices for Implementing QAQC in Oil and Gas Construction

Developing a Comprehensive QAQC Plan

A well-defined QAQC plan outlines the quality objectives, responsibilities, and procedures required for a project. It should be developed during the project's initial stages and include input from all stakeholders, such as project managers, engineers, and contractors. The plan should show quality objectives and also detail the project's scope, schedule, and budget, ensuring all parties understand their roles and expectations.

Establishing Clear Quality Standards

To ensure consistency and adherence to industry standards, it is essential to establish clear quality requirements for all project components. These requirements should be based on relevant industry codes, standards, and regulations, such as the API (American Petroleum Institute), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization) guidelines. By using customer requirements and setting clear quality standards, companies can avoid costly rework, delays, and potential safety hazards.

Implementing a Rigorous Inspection and Testing Regime

Regular inspections and tests are crucial for identifying defects and non-conformances early in the project. This includes material testing, quality audits, welding inspections, non-destructive testing (NDT), and pressure testing. By implementing a rigorous inspection and testing regime, companies can address any issues promptly and avoid potential failures or accidents.

Training and Certifying QAQC Personnel

Well-trained and certified quality assurance and quality control personnel are essential for an effective QAQC system. Such personnel include quality managers, inspectors, and technicians who are responsible for overseeing the quality assurance processes. Companies should invest in ongoing training and certification programs to ensure their QAQC team has the necessary knowledge and skills to perform duties effectively.

Continuous Improvement and Lessons Learned

An essential aspect of QAQC is continuous improvement, which involves evaluating performance and identifying areas for enhancement. Companies should maintain a "lessons learned" database to capture information from previous projects and use this knowledge to improve future performance. Regular audits and reviews should also be conducted to assess the effectiveness of the QAQC system and implement any necessary changes.

Benefits of Implementing QAQC in Oil and Gas Construction

Improved Quality and Reliability

Implementing an effective QAQC system in oil and gas construction projects ensures that materials, components, and processes meet the specified quality requirements. This results in improved quality and reliability of the constructed facilities, reducing the likelihood of operational disruptions, failures, and costly repairs.

Enhanced Safety

Safety is a paramount concern in all construction activities in the oil and gas industry. A robust quality assurance and quality control system helps to identify and rectify potential safety hazards during the construction process, reducing the risk of accidents, injuries, and fatalities. By adhering to industry safety standards and implementing best practices, companies can create a safer work environment for their employees and surrounding communities.

Regulatory Compliance

Oil and gas construction projects are subject to various local, national, and international regulations. Implementing a comprehensive QAQC system ensures that projects comply with these regulations, reducing the risk of fines, penalties, and project delays.

Cost Savings

By preventing defects and non-conformances, an effective QAQC system can reduce the need for costly rework and repairs. This leads to lower overall project costs and higher profit margins for companies operating in the oil and gas construction sector.

Improved Reputation and Customer Satisfaction

Companies that consistently deliver high-quality, safe, and compliant oil and gas facilities gain a competitive advantage and enhance their reputation. This can lead to increased customer satisfaction, repeat business, and new opportunities for growth.

Implementing QAQC with FTQ360 Inspection Software

FTQ360 is a cloud-based quality management software that enables companies to easily create, manage, and track inspections and tests throughout the entire oil and gas construction process. By leveraging our cutting-edge technology, companies can improve quality control, safety, and compliance while reducing costs and risks associated with oil and gas projects.

To find out more about how FTQ360 can help your oil and gas company implement and run a QAQC system, sign up for a free demo.