Many oil and gas companies still use antiquated inspection techniques based on pen, paper, and spreadsheets. The industry is notoriously resistant to technological innovation, driven largely by managers', technicians', and "gatekeepers'" reluctance to trial technological innovations at worksites, their fears over productivity risks, and field workers' resistance to changing the familiar ways of conducting quality inspections.

This is unfortunate because oil and gas field service software allows oil and gas companies to accelerate ahead of the competition. How so?

Consider the following four benefits when considering using gas field service management software

- Increased Operational Efficiency: Professional gas field service software is designed to make your inspection processes more efficient, cost-effective, and overall improve your oil and gas operations and asset performance. The system takes care of the scheduling, assignment tracking, and reporting. This allows inspectors and maintenance teams to save time and reduce costs- something they wouldn't be able to do with existing paper-based inspections systems.

- Quality Program Improvement: You can save millions by reducing process waste and rework through improved quality performance visibility at every operational stage - including asset management, and maintenance management.

- Defect and deficiency reduction: Powerful inspection software comes with problem-solving features. Oil and gas businesses can proactively reduce defects and quality failures by learning from experience to find patterns in the data that would otherwise have gone unnoticed. This can reduce risk and prevent future problems, including environmental incidents. A sound inspection system also provides valuable audit tools to ensure compliance with regulations, HSE standards, NIOSH Rig Check, OSHA standards, ISO certifications, CMMI best practices, and more. It will show if your company is compliant with industry-specific requirements. This solution has a very seamless integration process that's very easy to learn.

- Compliance and Risk Verification: One of the most important benefits of using field service software is that it provides proof of compliance. The system can track and report all activities and data associated with quality inspections, ensuring that all standards are met. Good quality management inspection software will also help you establish and maintain consistent processes across all locations. This will help to improve quality performance and reduce process waste. Furthermore, a crucial part of any successful project is having a well-defined quality plan.

Field service software can help you to develop and track quality plans, assuring that all objectives are met. By automating your QA/QC processes, you can improve compliance rates to safety, environmental, and other regulatory requirements. Industry leaders that made the transition regret not using it earlier.

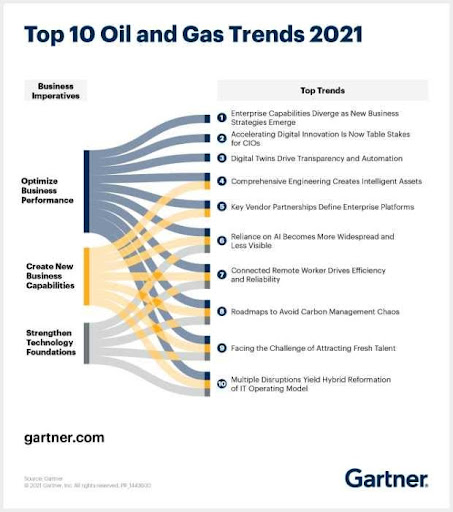

Accelerating digital innovation through field service software and other digital tools is now a critical business imperative for the oil and gas industry.

(Image source: Gartner)

However, you will only derive the four benefits listed above by using field service software specifically built for the oil and gas sector. The feature set must be universally better than every element of the old process it replaces.

At the heart of the solution is a single platform providing digital solutions for all necessary process steps and accessible to all parties who may serve a role in those processes.

Read 5 Steps to Measure Oil and Gas Vendor Quality

In this regard, there are three essential features to look for.

A Single Inspection Platform

A single inspection platform for digitizing all inspections, audits, and field data collection. Key features necessary specifically for oil and gas include:

- Test data collection tables

- Branching logic

- Calculation formulas

- Infinite ongoing inspections

- Inspection checcklists

- Dynamically expanding checklists

- Approvals

- Asset tracking

- Run as a mobile app or be mobile device friendly

The single platform for all inspections provides the foundation for a paperless environment, process efficiency improvements, and real-time performance tracking.

Read How to Effectively Manage Oil and Gas Facility Inspection Plans

All Project Participants Work on a Single Software Platform

A single platform allows all project vendors, third-party inspectors, engineers, suppliers, and service providers to conduct their QA/QC and HSE activities on one platform. Precision permission features are necessary for large oil and gas projects that involve many organizations and personnel with overlapping data access and security needs. They must coexist and interact without interfering with each other. The result is a platform that collects quality data, which leads to better decisions and fewer errors.

Tools for Managing Global Vendor Performance and Process Risks Using Data

In the competitive oil field services market, companies must measure performance across all geographies from a single platform. This is essential for assessing vendor quality performances and identifying risks that affect end-to-end activities within a project or process.

Data analytics must include the ability to drill down into data at multiple levels, including:

- Location

- Vendor

- Project phase

- Activity type

This enables companies to identify and correct quality issues impacting project success quickly. Process risks can then be managed proactively, mitigating potential business disruptions.

Global vendor performance measures enhance accountability for first-time quality and HSE where none existed before. Vendor-specific strengths and weaknesses enable a data-driven approach to vendor selection that reduces project-specific risks and improves the performance of the entire vendor base. Analysis of corrected deficiencies for classes of well equipment and tools focuses QA/QC on a data-driven approach to reducing process risks and preventing failures.

Data should also integrate into company data lakes for inclusion in corporate analytics and, more generally, support corporate-wide digitization initiatives. The contrast with paper-based and spreadsheet methods is like the transition from slide rules to electronic calculators.

These three essential features will help you get the most out of your oil and gas field service platform. By ensuring that your software has these features, you can ensure that you are getting a platform specifically designed for the oil and gas industry.

With this platform, you can improve efficiency, accuracy, and safety in your field operations.

If you are field technicians looking for oil and gas inspection software that has these essential features, be sure to check out FTQ360. Our software is designed specifically for the oil and gas industry, and it includes all of the features mentioned above. We also offer a free trial to try out our software for yourself.

Get the free demo to learn more about FTQ360.

![[DOWNLOAD THIS GUIDE TODAY] HOW INSPECTION APPS ARE DRIVING DIGITAL TRANSFORMATION IN THE OIL & GAS INDUSTRY](https://no-cache.hubspot.com/cta/default/3353989/8b58e27f-154e-49a2-beaa-d972aede0717.png)