Laws for the oil and gas industries are among the most complex ones in the world. For that reason, it is very important to ensure your oil and gas operations take every precaution available.

Oil and gas facility management is a complex and challenging process. It requires a lot of planning and coordination. There are so many things to keep track of, and it seems like there's always something that needs attention. Regular inspections are essential for maintaining the safety, efficiency, and effectiveness of oil and gas facilities.

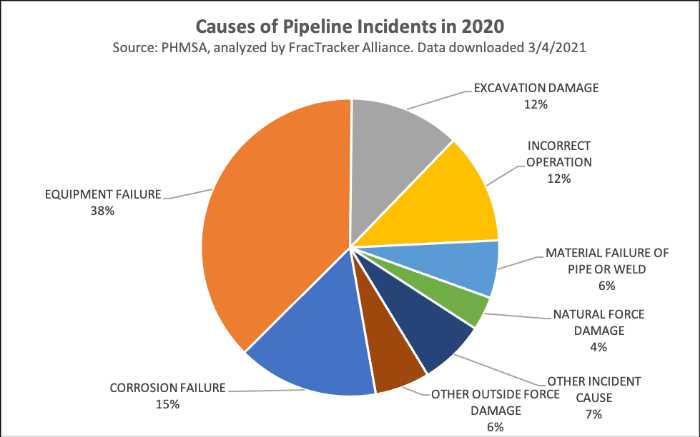

Unfortunately, the oil and gas industry continues to have a high rate of incidents and old inspection techniques have proven not to be sufficient. For example, in 2020, there were 614 pipeline incidents reported by oil and gas producers in the US that caused over $258 million worth of damage. Most of these incidents were caused by equipment and corrosion failures, which were avoidable with proper and timely inspections.

(Image source: Fractracker.org)

One of the most important aspects of oil and gas facility maintenance is creating and implementing an inspection and test plan (ITP). This plan will help you stay on top of maintenance and operations tasks, ensuring that your facilities operate without incident. There are several ways of planning and testing. Non-destructive testing methods (NDT methods) are among the most popular ones for many steps in your project life cycle.

This blog post will discuss some tips for creating an effective ITP to manage oil and gas maintenance inspections effectively.

What is an ITP?

An ITP is a checklist of required inspections used in the oil and gas sector. It's a plan outlining the tests and inspections you should conduct throughout each phase of the oil and gas facility inspection. Because it is such a vital part of an overall quality control strategy, knowing what an ITP is, why you should use one, and how to get the most out of it is critical for the proper maintenance of oil and gas facilities.

In short, an ITP is a comprehensive description of all the required inspections of equipment and facilities. It is a combination of two types of inspections: equipment inspections (static) and process inspections (dynamic).

Oil and gas inspection plans are critical for regulatory compliance, and for performance monitoring and optimization. The challenge is that setting up an inspection plan and keeping it updated as the facility changes can be a time-consuming task.

Static equipment inspections are based on the equipment itself, including safety, operation, maintenance, regulatory compliance and so on. They focus on each piece of equipment in a facility.

Dynamic process inspections focus on processes or systems at a particular facility. They involve many pieces of equipment that interact with one another to perform their functions.

Read How to create an Oil and Gas Walkthrough Inspection Checklist

Why use an ITP for Oil and Gas Facility Management?

If you're not utilizing ITPs in your quality management program, there are several reasons to consider doing so. Starting with an ITP plan makes it clear to everyone in the facility what they're supposed to do. It also explains to stakeholders what they can anticipate during each inspection stage. The ITP displays which tests and inspections are complete and pending.

Using an ITP as part of your quality facilities management procedure helps to ensure that people are held accountable for conducting the required inspections. In many situations, if a check is missed, you can't complete it later. By having a plan for inspections and tests, you can ensure that no areas of your facility are neglected. Additionally, an ITP can help improve operations by highlighting any areas that need improvement.

As a Facilities Manager or Operations Manager, it is accepted that you need some kind of Inspection Test Plan (ITP) to ensure that your inspections are completed on schedule and to the correct standard

What is included in an Oil and Gas Industry ITP?

An effective ITP will include all necessary inspections and tests for your oil and gas facility. You should tailor it to your specific needs, so it may vary from one facility to another. However, some general items are typically included in an ITP:

- Test or inspection needed

- Test or inspection frequency

- Required inspector types

- The person responsible for the inspection

- Completion dates

- Notes and comments

- Hold points - a mandatory verification point beyond which further action requires authorization.

Inspection specifications are organized in a simple-to-navigate layout that is easy on the eyes. The most important aspects of the inspection standards are included for quick reference.

How To Create an ITP?

It may seem like an impossible task to construct an ITP if you've never done it before. How can you possibly develop all the tests and inspections required on an oil and gas facility?

Thankfully, you don't have to define all the details of every ITP checklist. All you need to do is create an outline to follow based on your specific facility, industry, and regulatory standards. For example, NIOSH Rig Checklist can be used as a template for oil and gas inspection checklists.

This general framework will give you a starting point for creating an ITP that meets your needs.

Once you have your outline, the next step is to fill in the details. You'll need to specify which inspections are required and how often they should be done. Who is responsible for conducting each inspection? What completion date should be used? Are there any hold points that require special attention? What are the major milestones when you must complete critical inspections?

This process can be time-consuming, but it's essential to get it right. The more detailed your ITP, the better it will work for you. It may take some effort up front, but having an effective inspection plan in place will save you time and headaches down the road.

Enhancing an ITP with Software

Although paper forms are still used to create an ITP, today's technology has made it much simpler to manage an inspection plan.

Using a software program allows you to create custom inspections checklists, track inspector progress, generate reports, and more. Having all this information at your fingertips makes it easier to keep your oil and gas facility running smoothly. For example, if an inspector misses an inspection, the software can help you quickly identify the area that needs attention.

You can also set up dependencies and notifications to guarantee you don't miss any inspections. You can also quickly produce reports for stakeholders who want to know how far the inspection has progressed and the proportion of it completed.

An effective inspection plan is critical for oil and gas facilities. Using an ITP, you can ensure that all areas of your facility are checked regularly, and no stone is left unturned. Additionally, using software to manage your inspections can help improve operations by providing instant access to data and reports.

If you're looking for a way to improve your inspection plans, consider FTQ360 inspection management software. Our cloud-based software will help you effectively manage your oil and gas facility inspections. Get in touch today if you'd like to learn more about how FTQ360 can help you start using ITPs for your oil and gas facility inspections.