QAQC inspection services within the oil and gas industry are an essential beast that is embedded into every component, tool and system. Inspection techniques need to deliver results in terms of quality and safety, ultimately leading to a highly productive uptime of the facility. There are several ways to conduct your testing but NDT methods (non-destructive testing methods) are utilized the most in the oil and gas industry.

This explains why so much resource is invested in QAQC processes so that it is right first time.

This blog post will reveal practical quality control tips to help oil and gas sector companies and inspectors improve inspection techniques and guarantee compliance with company, regulatory, and industry standards for their oil and gas operations.

Eliminating non-productive time and streamlining QAQC processes produces more output with less effort with the end product being more reliable results.

Eliminate the Three Biggest Time Wasters

Three main things can waste time during an oil and gas inspection: using spreadsheets to document equipment inspections and visual inspections, overcomplicating the handling of deficiencies and non-conformances, and using email as your quality management platform.

- Using spreadsheets to document inspection reports: Many quality managers still use spreadsheets to record their visual inspection. Unfortunately, this can be very time-consuming and prone to errors. Spreadsheets are helpful, but an inspector still needs to take notes on paper and type them into the spreadsheet later – effectively doing the same task twice. Consider how much time you could save if you had a tool that allowed you to input all of your inspection services data directly into a mobile device (phone or tablet) instead of the standard practice of importing transcribing information into a spreadsheet.

- Overcomplicating the handling of deficiencies and non-conformances: When a defect or non-conformance is found, it is crucial to handle it quickly and efficiently. However, by its very nature, filing a simple non-conformance report is complicated and fraught with delays. And progress is dependent on the report completion.

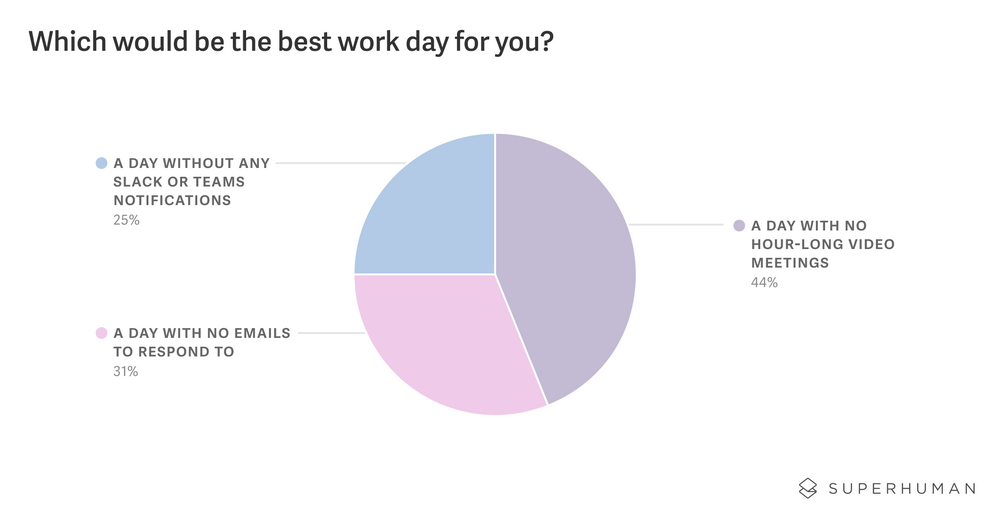

- Email as your quality management platform: Email is not a good platform for quality management or a to-do list. It can be challenging to track who has received and read emails, and it can be easy to lose important messages in the clutter. Furthermore, while email is a valuable business tool, it is a time-waster and inefficient for oil and gas industry inspections. Missing an email is an easy thing to do however the consequences can be dire. In addition, email causes fatigue and a feeling of being overburdened, according to a recent survey.

(Image source: Superhuman.com)

Inspection Checklists

A well-constructed inspection checklist can help you focus on the most important items during an inspection, avoid duplication of effort, and ensure that all required items are inspected.

We use many different techniques when it comes to inspections, liquid penetrant testing being some of the most common ones.

The best checklists are tailored to the specific facility or equipment being inspected, and they should be reviewed and updated regularly.

It is also helpful to have different checklists for different types of inspections (pre-job walkthroughs, start-up inspections, routine inspections, and so on. For oil rigs, ensure you make use of NIOSH Rig Inspection Checklists.

Check out FTQ360's Oil and Gas QAQC Platform:

The Importance of Communication

Communication is critical during oil and gas inspections. Good communication between inspectors and other personnel involved will help avoid confusion and ensure that all aspects are carried out effectively.

Using email to update the status of reviews and approvals of inspection reports becomes complicated when there are multiple versions of the same inspection reports on a long email trail.

One way to improve communications in the oil and gas industry is to use an inspection platform that ensures all stakeholders have real-time access to the latest information on defects, non-conformances, recommendations, the actions taken, and all other pertinent information.

Read How Inspection Apps Improve Oil & Gas Equipment Reporting

Leverage the Power of FTQ360 Oil and Gas Inspection App

The FTQ360 oil and gas inspection app is a mobile inspection application that allows quality managers to improve their specific inspections to adhere to government regulations and avoid unnecessary penalties and risks. It solves all pre-inspection problems, eliminates time-wasting, comes pre-loaded with all the checklists you would ever need, and streamlines communications. Additional features include:

- Cloud-based but can work offline: The FTQ360 oil and gas inspection app is cloud-based, which means it can be accessed from any internet-connected device. However, it also works offline, so you can continue working even if there is no internet connection and synchronize later.

- Problem-solving analytics at your fingertips: With the FTQ360 oil and gas inspection app, you have access to problem-solving analytics that will help you quickly identify and solve problems.

- Configurable and customizable to fit your project: The FTQ360 oil and gas inspection app is fully configurable and customizable to fit your specific project requirements. You can choose what information is displayed on each screen, customize the checklists to match your particular needs, and set up your own risk-based inspection template for inspections in oil and gas industry services.

- Inspector settings and options for Company, Third-Party, and Self-Inspectors: The FTQ360 oil and gas inspection app allows you to set different inspector profiles for company inspectors, third-party inspectors, and self-inspectors. This ensures that the correct information is displayed for each type of inspector.

Sign up for a free demo for more information on how the FTQ360 oil and gas inspection app can help you improve your inspection techniques.