Certification of your quality control and quality assurance program is required if you're in the modular construction industry. Not only do the modules themselves need to meet the building codes, but your factory construction process also needs to meet precise QAQC and follow project quality specifications as per the program requirements. Therefore, setting up a construction quality control program that meets all applicable quality standards is vital.

This blog post will discuss establishing a modular QA/QC Construction Program using FTQ360 quality management software

QAQC in Modular Construction

Modular construction factories must have their QAQC process certified by county factory-built housing guidelines and state residential building codes to manufacture modules for their construction projects. There are a few reasons for this:

· To ensure construction modules meet code requirements and thus guarantee the quality and safety of the modular units being produced.

· To give customers peace of mind that they're getting a quality product.

· To protect the reputation of the modular construction company

Accreditation bodies rely on your Quality management processes because they provide evidence that you consistently produce quality modular homes.

A comprehensive QA/QC program will help ensure that all modular components comply with building codes and guidelines and meet the highest quality standards.

Check out FTQ360's QAQC Setup for a Modular Manufacturer:

Essential Elements of a Solid QA/QC Program in Modular Construction.

-

Designated Quality Manager and a QA/QC Team: The quality manager is responsible for developing a project quality plan, and implementing, and maintaining the quality management system. They should also have quality control inspectors to carry out quality control activities such as inspections and tests.

-

Streamlined Communications: Communication is essential for quality control. There should be clear lines of communication between the quality manager, project manager, construction manager, and all other relevant parties. In addition, quality control activities should be well documented and reported.

-

Quality Assurance Surveillance: Quality assurance surveillance monitors the quality of work throughout the project to adhere to the quality plan. This includes everything from inspections and tests to reviewing project documents.

-

Quality Criteria for Suppliers and Subcontractors: All suppliers and subcontractors should be required to meet quality criteria. This will help to ensure that all materials and components meet quality standards.

-

Modular Construction Quality Specifications: The modular construction quality specifications should be clearly defined and documented. These specifications should be used to guide all quality control activities.

-

Inspections and Tests: Inspections and tests should be conducted throughout the project to ensure that all quality standards are met.

-

Non-conformance Control: Any non-conformances should be immediately addressed and corrected. A system should be in place to track and report all non-conformances.

FTQ360 ensures all of these quality control elements are in place.

QAQC Setup for a Modular Manufacturer Using FTQ360

FTQ360 is a construction quality management software that helps construction companies improve their projects' quality and safety to adhere to said project specifications from beginning to end. The software offers a quality control program that is ideal for modular construction companies.

The FTQ360 QAQC Program includes everything you need to set up a quality control program for your modular construction business, including quality control templates, checklists, and reporting tools.

Below is the process of setting up a modular home manufacturer's digital quality control program.

FTQ360

FTQ360 quality control software is easy to use and configurable to fit the specific needs of your modular construction business. For most modular construction companies, the manufacturing process involves several stages, from frame building to finishes. You will use FTQ360's intuitive features to create a quality control plan as well as quality control inspection checkpoints at each process stage.

Self Inspection and Recording

The QA/QC system you create must pass the certification requirements of your local factory-built housing guidelines and residential building codes. You may also want to add your in-house standards. For example, the production team can self inspect with oversight by a small QA team, and the system must be paperless.

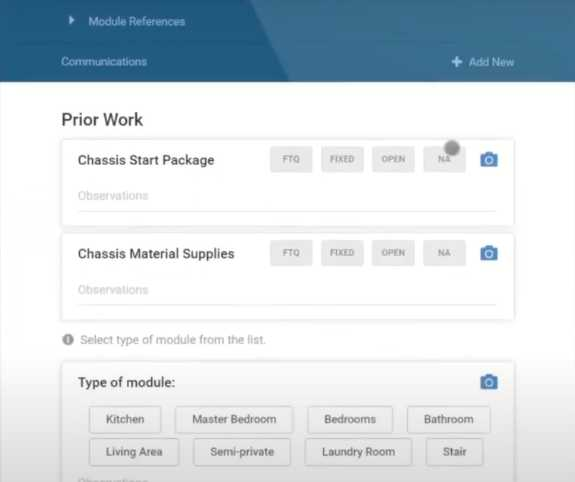

Here's what the QA/QC looks like using FTQ360:

-

First, each station self inspects the modules they produce.

-

The first part of the inspection checks prior work, engineering documents, and material supply.

-

The second part is for the completion of their work. They choose the module features, and FTQ360 uses "if-then" logic to dynamically adjust inspection checkpoints for the particular module type and options.

-

The inspector records critical measurements like frame dimensions, takes photos of details and verifies critical checklist items using a tablet or smartphone.

-

For each checkpoint, the inspector evaluates items that meet first-time quality with no problems. These are marked as Okay in FTQ360. Items with issues that still need corrections are marked as Open and assigned a priority designation. This action automatically puts them on the Issues List until they are fixed. After remediation, they are marked as Fixed, and hours of delay and reason codes are recorded.

(Image source: FQ360 Dashboard)

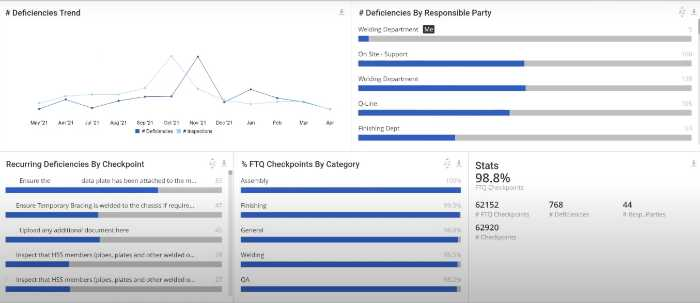

Reporting and Deficiency Action

After all the corrections are made, and the inspection has passed, printed PDF reports document the proper completion of the module and are automatically saved to the project repository.

The production team can monitor the inspection status of each module as it progresses through each station. This visibility ensures that the inspections are performed, deficiencies are corrected, and there's proof that each module was constructed correctly.

Quality dashboards give the production team insight into the avoidable issues, unnecessary costs, preventable delays, and where they occur.

(Image source: FQ360 Dashboard)

Monthly, each station team targets a top recurrent issue for prevention. All of the codes and data integrate with common ERP tools link directly to the FTQ360 databases to document the Quality Management Control program.

To learn more about how you can leverage the power of FTQ360 to establish a modular QAQC construction program, sign up for a free demo.

![[FREE EBOOK] Your Complete Guide to Achieving First Time Quality](https://no-cache.hubspot.com/cta/default/3353989/8c80b65c-b362-4e46-af1b-0ecf2d1581db.png)