No matter the size or type of construction project, quality assurance (QA) and quality control (QC) should be top priorities.

Starting a quality assurance and quality control (QAQC) program on your new construction project is essential to ensuring that you deliver a successful project that conforms to the project design, meets customer requirements and complies with local building codes. The right program will provide confidence to not only your customers but your entire team.

When planning a QAQC program, it’s critical to create a building construction quality control plan that aligns with project goals, codes, and standard and follows best practices throughout the quality management process.

What is a QAQC Plan?

The quality assurance and quality control plan (QAQC plan) is a document that outlines the process for managing and executing quality assurance and quality control activities throughout the project lifecycle. The QAQC plan should include the following:

- Customer Requirements and Expectations - This section of the QAQC plan should include a project-wide customer communication strategy, customer expectations and acceptance criteria, a communication log and a communication tracking matrix to help you track these items throughout the project lifecycle.

-

Quality Assurance Program - This section of the QAQC plan should include the high-level program for quality assurance on the project, including quality assurance roles, responsibilities, and authorities, quality assurance deliverables, quality assurance communication plan and quality assurance metrics.

-

Quality Control Program - This section of the QAQC plan should include the high-level program for quality control on the project, including quality control roles, responsibilities, and authorities, quality control deliverables, quality control communication plan and quality control metrics.

Quality Assurance (QA) and Quality Control (QC) in Construction

So, how do you apply QA and QC to the construction industry? Let's take the example of an ongoing project. Numerous activities are performed on the site daily, based on the different aspects that need coverage in the construction process. The project team has two quality management options:

-

Conduct regular quality inspections through QC checks, analyze the data, and use it to eliminate or minimize potential problems throughout the project.

-

Create a general quality assurance plan using data from past projects, maintain a record of all issues and perform a quality control check at the end of the project.

The problem with the more popular second approach is that it creates a disconnect between QA and QC and we need consistency with both. The typical result is that quality issues are not well defined, quantified and can only be mitigated after a quality control check.

The ideal situation is a quality management system that fuses quality assurance with quality control. Issues should be well-identified and analyzed and then used to create a workflow that systematically eliminates or minimizes them saving you time and money.

Essential Elements of a Solid QAQC Program in Construction

To get an idea of how to incorporate QA and QC in your construction project in line with the most up-to-date industry standards, let's look at the essential elements of a solid QAQC program.

Designated Quality Manager and QA/QC Team

The first step is to appoint a quality manager responsible for the quality management system on your construction project who understands the methods and procedures needed. The quality manager should develop a plan outlining all QAQC activities from start to finish.

The quality manager will also assemble a quality assurance/quality control team. This team should include representatives from each discipline on the project. The quality team's responsibility is to carry out the quality plan and report any issues to the quality manager.

More importantly, the quality manager should be independent of the construction team. It is a good idea to develop a project quality control organizational chart that shows the quality manager's position in relation to the project management team, construction team, and quality assurance/quality control team.

Streamlined Communications

Clear and concise communication is essential for quality assurance in construction. Therefore, the quality manager should establish a quality control system that includes regular meetings, progress reports, and a shared document repository.

This approach ensures that everyone on the project is aware of quality issues and can provide input on how to resolve them.

Quality Assurance Surveillance

A quality assurance surveillance plan should be in place to monitor subcontractor and supplier performance. This plan should include regular site visits, audits, and reviews of quality control records.

Quality assurance surveillance aims to identify quality issues early and prevent them from becoming problems.

Quality Criteria for Subcontractors and Suppliers

The quality manager should develop quality criteria that all subcontractors and suppliers must meet. These criteria should be based on the project's quality specifications and consistently applied to all subcontractors and suppliers.

Project Quality Specifications

The quality manager should develop quality specifications for the project. These specifications should be based on the project's quality requirements, design, building codes, and regulations and should be used to evaluate all subcontractors and suppliers, materials, and all work performed.

Inspections and Tests

Inspection and testing are essential for product quality control in construction. Develop a plan of all inspections and tests you intend to conduct during the project's duration. This should include regular inspections of materials, workmanship, and equipment. This plan should also include testing materials, soils, concrete, and so forth.

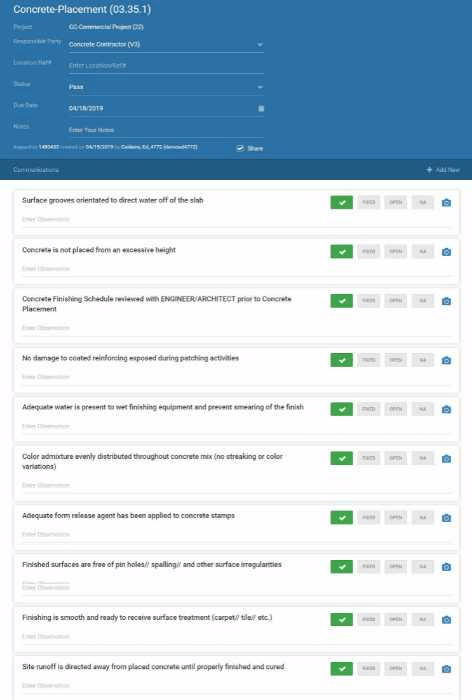

Create an inspection checklist of all items you intend to inspect to use a pre-made checklist that's appropriate for your project. Below is a screenshot of a sample concrete placement checklist from FTQ360 Quality Management Software.

Nonconformance Control

Use a nonconformance control system to track and resolve quality issues. This system should include a procedure to log quality issues, identify defects, investigate the root cause, and take corrective action.

Project Completion Inspections

Perform a final inspection at the end of the project to ensure you have met all quality specifications. This inspection should include a review of all work performed, materials used, and equipment installed.

How to Build a Construction Quality Control Plan (QAQC Guide)

A building construction quality control plan is a comprehensive document that outlines how quality will be managed, monitored, and enforced on a construction project. Whether you're managing a residential build or a large-scale commercial development, a well-structured QC plan helps ensure that all project deliverables meet design specifications, safety codes, and client expectations.

Below is a step-by-step guide to developing an effective quality control plan for building construction projects.

1. Define Project Scope and Quality Objectives

Start by outlining the overall scope of the construction project and specifying measurable quality objectives. These should align with the client’s requirements, applicable building codes, and any contractual obligations.

Example quality objectives:

-

Concrete compressive strength must exceed 28 MPa

-

All work must pass local code inspections on the first attempt

-

Project to meet ISO 9001:2015 quality standards

2. Assign QA/QC Roles and Responsibilities

Establish a clear quality management structure by assigning dedicated QA/QC roles, including:

-

Quality Manager – Oversees the QA/QC program

-

Site Quality Inspector(s) – Conducts routine inspections

-

Document Control Lead – Maintains quality records and forms

-

Subcontractor QC Representatives – Ensure compliance at task-level

Include a project quality org chart to show reporting relationships between QA/QC personnel, construction teams, and management.

3. Develop Inspection and Test Plans (ITPs)

Create a detailed Inspection and Test Plan (ITP) that identifies:

-

What will be inspected/tested (e.g., rebar placement, concrete pours, MEP installations)

-

Inspection frequency

-

Acceptable quality standards

-

Responsible party for sign-off

Each trade or construction phase should have its own ITP aligned with drawings, specifications, and manufacturer guidelines.

4. Set Quality Documentation Requirements

Quality control is only effective if it's well-documented. Include a section in your plan that outlines:

-

Inspection checklists to be used

-

Daily/weekly QA/QC reports

-

Nonconformance reports (NCRs)

-

Corrective action forms

-

Material approval records

-

Photo documentation protocols

Use centralized quality software (like FTQ360) to maintain version control and share documents in real time with project stakeholders.

5. Define Acceptance Criteria and Standards

List the building codes, engineering standards, and product specifications that define your project's quality benchmarks. Examples:

-

International Building Code (IBC)

-

ACI 318 for structural concrete

-

ASTM standards for materials

-

ISO 9001 for quality systems

This helps ensure consistent evaluations throughout construction and provides a basis for third-party inspections.

6. Implement a Nonconformance and Corrective Action Process

Outline your process for identifying, documenting, and resolving nonconformances. This process should include:

-

Logging defects or quality issues

-

Root cause analysis

-

Immediate corrective actions

-

Preventive actions for future avoidance

-

Closeout procedures

Be proactive in using data from inspections to identify patterns and take preventative measures early.

7. Plan for Final Inspection and Handover

The final step in the QC plan should describe the project closeout process, including:

-

Final inspection procedures

-

Punch list generation and tracking

-

Handover documentation (O&M manuals, warranties, as-builts)

-

Client sign-off and acceptance criteria

You may also want to include a post-project quality review to feed into your continuous improvement process.

Sample Structure of a Construction Quality Control Plan

| Section | Description |

|---|---|

| Executive Summary | High-level overview of QC strategy and goals |

| Roles and Responsibilities | Detailed org chart and individual duties |

| Inspection & Test Plans | ITPs by trade or construction phase |

| Documentation Control | Forms, logs, reports, retention policy |

| Acceptance Criteria | Applicable codes, specs, tolerances |

| Nonconformance Management | Procedures for defect tracking and resolution |

| Final Inspections | Closeout processes and client handover checklist |

Pro Tip:

Consider integrating your quality control plan with construction management software to centralize inspection checklists, generate quality reports, and streamline subcontractor communication. FTQ360, for example, provides templates and tools that align directly with this type of plan.

Using FTQ360 Quality Management Software

FTQ360 is process-oriented quality management software for streamlining quality assurance and quality control in construction. This software provides a centralized quality control system you can use to manage quality assurance surveillance, inspections, and tests.

In addition, FTQ360 also provides a non-conformance control system for tracking and resolving quality issues. Some of the main features at a glance include:

-

Streamlined Communications

-

Pre-loaded inspection checklists

-

Consistent processes ensure the inspection and testing team conduct inspections the same way every time.

-

Comprehensive project quality plans

-

Built-in safety compliance and risk reduction

-

Powerful analytics via insightful performance dashboards and reports

-

Proactive defect reduction functions and tools

For more information on how FTQ360 can help you start a QAQC program on a new construction project, book a free demo or contact us for more details.