A Construction Manager's Guide to Quality Management.

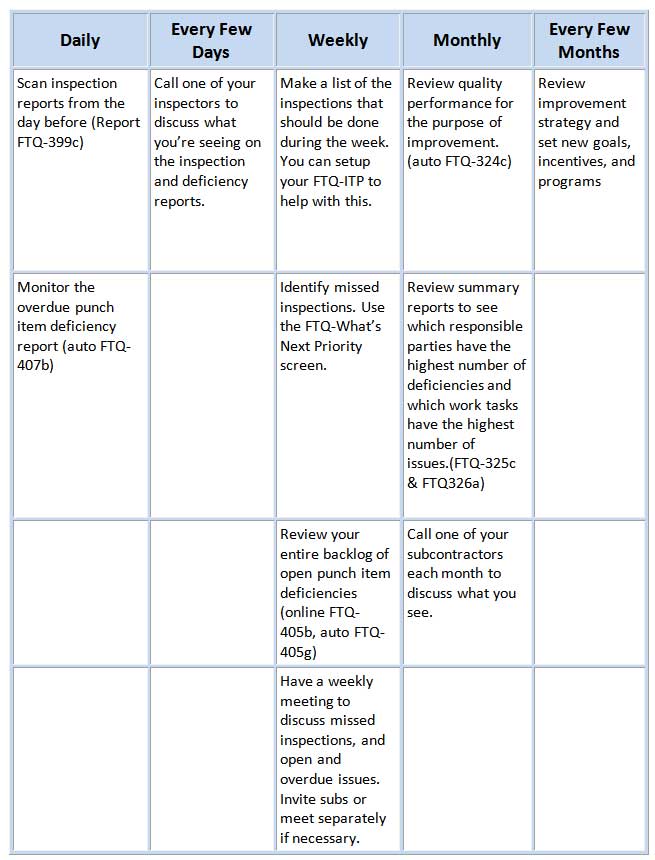

With the appropriate tools and a strategic approach, you can effectively spend 20 minutes a day managing project quality through quality management systems. These systems, coupled with total quality management principles, contribute to customer satisfaction by providing actionable information and facilitating necessary actions.

What is Quality Management in construction?

Construction quality management is a set of tools and techniques used to help ensure a project meets its specifications, stays within budget, and is completed on time, within the schedule, and within the budget.

Construction quality management is the process of effectively managing the entire project lifecycle, from planning through execution to completion, using a quality management system (QMS). It involves setting priorities, making informed decisions, and implementing continuous quality improvement practices. By utilizing quality management software, monitoring and managing these decisions becomes more efficient and streamlined.

Why do you need a quality management program?

Good project management is a must for any business that wants to meet customer needs, keep improving quality, and achieve measurable goals.

Quality management programs help to keep track of both the project and the processes, so more accurate tracking of information and resources are available. A quality management program is one of the basic tools of a successful project. It helps identify, manage, and control risk while providing the information and resources necessary to do a project right.

How to develop a fault-proof quality management program

Quality control in construction businesses poses significant challenges, particularly in meeting customer expectations. Developing a successful quality management program requires careful consideration of the quality system and a commitment to continuous improvement. While there is no definitive approach, following six steps and maintaining consistency in your quality systems can lead to a robust program that effectively addresses customer expectations.

1. Define your quality objectives

2. Identify the project quality factors

3. Develop a quality management system

4. Design the monitoring plan

5. Implement the quality management program

6. Evaluate and adjust based on results

Inspections

First your QA/QC system needs to operate correctly. Then you can monitor the QA/QC system for deviations so you can guide it back on track.

Plan what should be inspected next week.

There is no accountability without responsibility, so make a list of what should be inspected and the job position that will do the inspecting. You can use your inspection and test plan (FTQ-ITP) and/or schedule to help with this.

If you don’t have a QC staff, it should be your superintendents or supervisors doing the inspections. Limit your management inspections to an audit/surveillance role. 10 minutes per week/2 min. per day.

Daily, scan inspection reports.

To ensure quality assurance and regulatory compliance in the field of medical devices, automatically receive an email containing all inspections conducted the previous day (auto FTQ-399c). Assess the reports to evaluate the quality of the information provided by inspectors and identify any issues. Schedule periodic discussions with inspectors to maintain effective document control and encourage continuous improvement. By dedicating just 5 minutes per day, you can enhance the inspectors' performance and uphold high standards.

Make inspection reports a requirement for schedule task completion and purchase order payments.

Use your management software to identify missed inspections and tasks (FTQ-What's Next Priority). Holds inspectors accountable for completing their inspections in a timely manner. 5 minutes.

Validate reporting of deficiencies during normal jobsite walks.

Look for marks on work or repairs not reported. 0 minutes extra (plus coaching time as needed).

Punch Items and Deficiencies

Secondly, manage current punch items and deficiencies. If your staff is still using old punchlist methods (i.e. paper, pencil and spreadsheet), show them how to use cloud-based punch list tools. Let the system automatically email you and your subcontractors daily reports of inspections, punch items, and overdue deficiencies. Then you can focus on managing instead of administrating.

Daily, monitor the overdue punch item deficiency report (auto FTQ-407b).

This report tells you that there was a problem that people thought should be fixed by now. Jump in to help if your experience says your field staff may need some horsepower to get a problem resolved. 2 minutes per day.

Weekly, review your entire backlog of open punch item deficiencies (online FTQ-405b, auto FTQ-405g).

Use open punch list deficiency reports to see each subcontractor’s backlog of open items. If a subcontractor is getting behind on its deficiencies, invite them to a meeting for a review. In time, your staff and subcontractors will learn to stay on top of their deficiencies – it only to stay ahead of your inquiries. 10 minutes per week / 2 minutes per day (plus meeting if necessary)

Quality Improvements

Third and last, use the inspection data to improve. Have the system automatically email responsible parties their inspection history (auto FTQ-329 weekly).

Review summary reports to see which responsible parties have the highest number of deficiencies and which work tasks (across all projects) have the highest number of issues.

Improvements will be made to issues that are well documented and known by everyone involved. No surprises!

Don’t waste time listening to complaints.

If it’s not important enough to record on an inspection report, it’s not important to you either. Explain that you need facts to fix the problem and gossip doesn’t help. Inspectors will learn to record issues just in case they need your help later. 0 minutes

Monthly, review quality performance for the purpose of improvement.

Prepare by running online reports of recent inspections, history of deficiencies, and quality performance reports (auto FTQ-324c). Study them and get some insights from your staff. Home in on recurring deficiencies and come up with an action plan. 20 minutes per month

Even though this plan averages less than 20 min per day (plus occasional meetings) it is a bit optimistic.

Regardless of how much time you estimate it will take, I think you’ll agree you can accomplish a lot with your QA/QC program (in a small amount of time) if you follow my approach.

![[FREE EBOOK] Your Complete Guide to Achieving First Time Quality](https://no-cache.hubspot.com/cta/default/3353989/8c80b65c-b362-4e46-af1b-0ecf2d1581db.png)