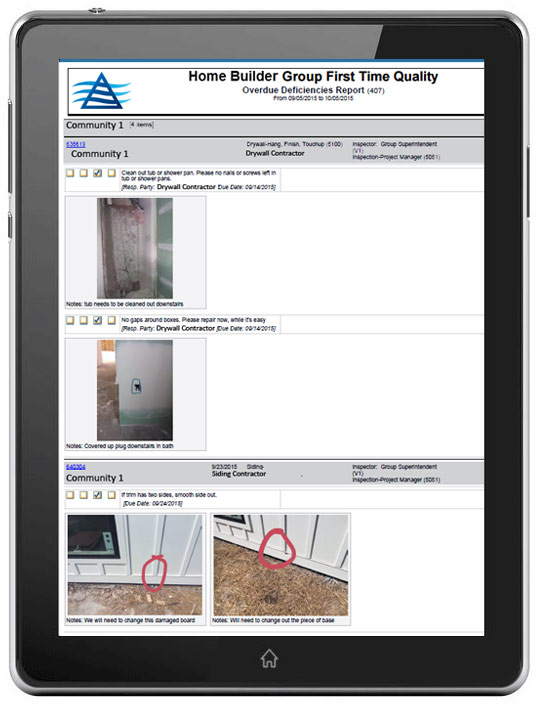

With FTQ360, you can see a list of a contractor’s open deficiencies across any number of inspections, punch lists, and corrective actions, all in one place. The software does the work of scanning for open items and corrective actions across all inspections and puts them all on one list.

With FTQ360, you can see a list of a contractor’s open deficiencies across any number of inspections, punch lists, and corrective actions, all in one place. The software does the work of scanning for open items and corrective actions across all inspections and puts them all on one list.

Here are some ways that you can use the power of punch lists to reduce project deficiencies.

Best Practises for Managing Punch Lists

Identify responsible party and set a deadline: When you inspect a project, identify the contractor(s) responsible for correcting open items. Set a deadline and a follow-up date with the contractor. Specifying time frames creates urgency and helps to keep things from stalling.

Set auto-daily reporting for project managers and resp. party: Both project managers and contractors should get automatic daily exceptions reports listing overdue items that need immediate attention.

Send weekly deficiency reports: With FTQ360, you have the ability to send each subcontractor weekly deficiency reports only for their responsible items. FTQ360 organizes their deficiencies by project for easy viewing.

Check out FTQ360's to Prioritize your Deficiencies:

You can also send project managers weekly deficiency list reports for their projects that organize deficiencies first by subcontractor, then by priority of the deficiency. Reports are sent automatically every week and are available online as needed.

Utilize deficiency reports in project meetings: This keeps contractors on task. Each item in a report has a clickable link that opens up the full inspection so you can review and update progress.

Deficiency punch lists are a powerful feature of FTQ360 that keep things from falling through the cracks and help to create overall consistency with your inspections.

More resources on Punch Lists

- 8 Steps to Better Construction Punch Lists

- Punch List vs Checklist: How to Improve Your Quality

- How to Quickly Cut Your Construction Punch List Defects

- Improve Your Punchlist System: Top Construction Tips

To learn more about FTQ360 Punchlist & Issue Tracking feature, Request Your Free Demo Today!