Who doesn't love efficiency? Efficiency means more for less. Nowhere is this mantra truer than in the oil and gas industry, especially now. Not only for operations but for QA/QC and Safety assurance as well as other related services. Oil and gas inspection services are critical for ensuring rigs' productive uptime and operating at full capacity - all whilst safeguarding employees and the environment. Not only is inspecting more important than ever, but the QA/QC and Safety programs must also be more efficient and productive than ever.

In oil and gas operations, inspection techniques like magnetic particle testing and liquid penetrant testing ensure equipment meets standards and drilling tools are flawless. These methods help identify potential problems early, preventing issues from becoming actual problems. However, conducting inspections can be demanding work, with inspectors gathering detailed data in remote locations and documenting everything to meet exact inspection standards for safety procedures.

After the physical and visual inspection, they then have to sit down and compile handwritten data and pictures into spreadsheets. This is followed by spending an inordinately long time writing deficiency reports – which historically, are also created manually and tracked using email and spreadsheets. The good thing about the visual inspections is that they are considerably faster and cheaper than other NDT methods.

Wasted time has the potential to delay reporting findings and correct deficiencies. Unplanned – but avoidable - downtime can also occur if inspections miss a detail that causes equipment failure, a broken downhole tool or worse. Delayed approvals and lengthy downtime have costly consequences and can hit your bottom line hard. Indeed, according figures cited in Petro Industry News, downtime costs oil and gas companies an average of $42 million a year – and up to $88 million in the worst case scenarios.

One way to save time on oil and gas inspections is to invest in onsite mobile inspection technology and cloud-based quality management software. Doing so eliminates time-wasting in the following areas.

Time Waster #1: Spreadsheets

There is no question that electronic spreadsheet programs such as Excel made computations and data analysis easier than with pen, paper and a pocket calculator – but they are no longer the optimal solution.

In the oil and gas industries, inspectors face the challenge of using spreadsheets and manual note-taking, resulting in redundant tasks. However, adopting non-destructive testing techniques and utilizing mobile devices (phone or tablet) for data entry can save time and ensure compliance with government regulations. Conducting inspections once and efficiently in the field removes the need for additional work at the desk later.

Mobile inspection tools eliminate the need to compile handwritten inspection notes and then transfer these into a spreadsheet. The inspector makes his inspection rounds, enters his observations directly into the inspection tool, and then generates a report with a simple tap which is instantly shared to the cloud.

Time Waster #2: Over Complicating the Handling of Deficiencies and Non-Conformances

Non-conformance occurs when equipment fails to meet set standards. The traditional method of dealing with deficiencies and non-conformances is to capture them in reports, send out emails to the people responsible for resolution, and track the progress using a spreadsheet. These reports are usually quite detailed and can take a long time to prepare when the process is manual. For example, a simple non-conformance report will contain the following:

- A description of the non-conformance (possibly with an image)

- A list of corrective actions needed to fix the non-conformance

- The responsible party tasked with correcting the issue

- Documented actions taken to correct the non conformance

- Acceptance of the corrective actions

From the above, it is clear that this is a complicated process. The last thing you want is to manage this process using email and spreadsheets.

In many instances, inspectors will also spend more time on a deficiency than the inspection itself.

Using mobile inspection technology streamlines gas industry inspections. Specific inspection software purpose-built for the oil and gas industry allows immediate on-site documentation of deficiencies or non-conformances. With a simple tap, the data is sent to the team responsible for resolving the issues, aligning with industry standards and saving time, removing frustration.

Time Waster #3: Using Email as Your Quality Management Platform

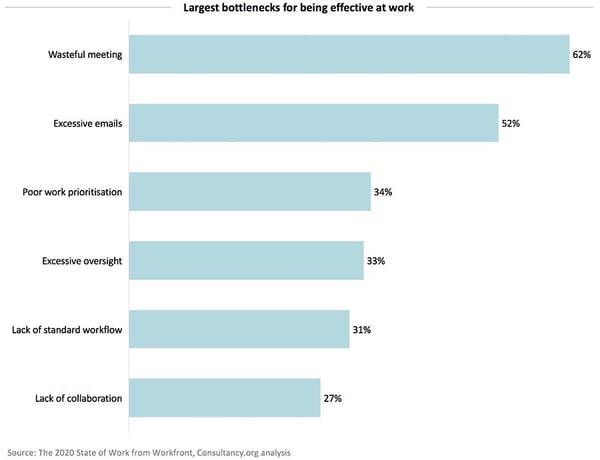

It is common for oil and gas professionals to use email as a to-do list. People spend an entire day responding to incoming email and fail to get any work done. According to a Consultancy.eu study – which polled 3,750 employees across the US, UK, Germany and the Netherlands – roughly half of work time is lost on inefficient tasks such as excessive emails and suboptimal processes, including poor work prioritization and a lack of standard processes for workflow and collaboration. Email overload is a sign of poor management. Some companies have gone as far as banning email at the workplace.

(Image source: consultancy.eu)

While email is an essential work tool in certain scenarios, sending, monitoring, and following up on emails as part of oil and gas inspections is inefficient and a huge time-waster.

The solution is a cloud-based quality management platform for better efficiency and accountability.

FTQ360 Oil and Gas Inspection Platform

To avoid these three time-wasters in your oil and gas inspections, consider using FTQ360.

FTQ360 is a cloud-based mobile inspection platform designed for the gas inspection industry and equipment inspections. It ensures operations adhere to the highest standards and holds inspection teams accountable. With this tool, you can easily demonstrate compliance to stakeholders, regulators, customers, and litigants.

The platform simplifies complex inspections and eliminates the need for spreadsheets. You can also plan and manage your quality control process for your non-visual inspections seamlessly. FTQ360 ensures you avoid outdated email practices for inspection and deficiency reporting workflows.

Reviewing, approving, and transmitting inspection reports in the oil and gas industry reduces from days to a matter of minutes. The tool also ships with powerful analytics to aid in your decision-making and regulatory compliance. It is highly configurable, customizable, and comes with free customer support. Book your free demo today and eliminate time-wasting during oil and gas inspections.

If you're looking for construction management software, we'd be happy to answer your questions and start you on a free trial of FTQ360.

Read more on Oil and Gas Inspections

- How to Create an Infallible Oil and Gas Inspection Checklist

- How Oil & Gas Inspection Apps improve Equipment Reporting

- How to Manage Oil & Gas Inspection Plans for your Facilities