With construction projects, the customer always comes first. They expect the best quality product possible, and it is the project manager's job to ensure they get it. In order to ensure quality control throughout the entire project, you must build proactive quality assurance (QA) into the project plan from the beginning.

What Is Proactive QA?

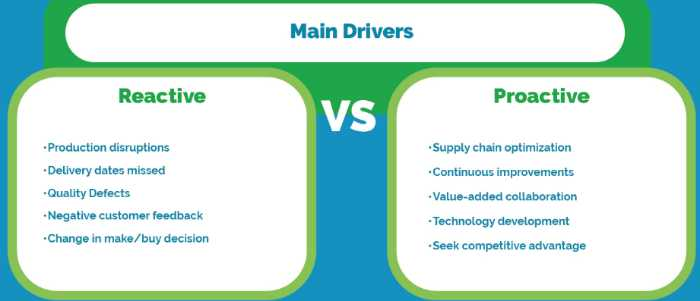

Proactive quality assurance (QA) and quality management systems are data-driven approaches to preventing defects and ensuring first-time quality performance. These processes use data from past construction projects to identify areas for improvement and implement strategies to prevent issues and defects from occurring. By catching issues early on, you can avoid potential delays and cost overruns. Quality improvement efforts can also help you avoid the need to fix mistakes after they've already been made.

(Image source: mexicomlogistics.com)

Key Benefits of Proactive QA

Several key benefits come with incorporating proactive QA into your construction planning process:

-

Proactively prevent defects and improve first-time quality performance: This is done by analyzing data from past projects so that you can fix potential problems before they cause delays or other cost increases. In addition, this leads to improved customer relationships as they are more likely to be satisfied with the end product if there are no defects or issues.

-

Reduce non-productive costs: By catching potential problems early on, you can save time and money that you would otherwise spend fixing defects.

-

Improved customer relationships: By ensuring a high level of quality, you build trust and credibility with your customers, which leads to long-term relationships.

Best Practices for Quality Construction Project Planning

A few best practices should be followed when incorporating quality control into your construction plan.

Take a proactive view and define quality standards early on in the project

Take a proactive view and define quality standards early on in the project. This approach will ensure that everyone on the project team is on the same page from the start and that there are no surprises later on.

Use clear and concise language in the construction management plan. Ambiguous or confusing language can lead to misunderstanding and errors down the line.

Make sure that the construction management plan is accessible to all relevant parties. This includes construction workers, subcontractors, suppliers, and so on. Having a centralized location for the construction management plan will help to ensure that everyone can easily refer to it as needed.

As a construction project manager, it is essential to ensure that quality planning is an integral part of your project management approach. To do this, you should establish a quality management system standard to guide your efforts. One critical aspect of quality planning is to regularly review and update the plan as needed to reflect changes in the construction project. For example, the construction schedule may be adjusted, new materials may be needed, and so on. By keeping the plan up-to-date, you can ensure that everyone involved in the project is on the same page and that there are no surprises later on.

Set up a quality assurance team

One of the most critical steps in construction project planning is to set up a quality assurance team. This team should ensure that quality standards are being met at every stage of the construction process. They should also be available to provide advice and guidance to construction workers if they encounter any problems.

To ensure that the quality assurance team operates effectively, it is essential to appoint an experienced and qualified construction project manager who is well-versed in quality management system standards. The project manager should possess a thorough understanding of these standards and have the ability to communicate them effectively to all stakeholders involved in the construction project. Moreover, the project manager should be capable of developing and managing a construction project schedule that takes into account the project's quality requirements.

It is also vital to put in place a system for monitoring construction progress and quality. This could involve carrying out regular audits of construction sites and using independent experts to assess the quality of construction work.

Collect data and track progress

It is important to collect data throughout the construction process and track progress against the construction plan. This will help identify any potential delays or cost overruns so that you can take corrective action promptly.

Communicate with all stakeholders

Good communication is essential for any project, but it is imperative when quality control is a priority. Make sure that everyone involved in the project knows the quality standards and what they need to do to meet those standards.

Use the Right Tools and Technology

Construction project management software can automate many of the tedious tasks associated with construction planning, such as data tracking and progress reports. This not only saves time and resources, but also helps to ensure that quality inspections are carried out correctly.

Functions and Features of FTQ360 Construction Management Software

To ensure that your construction project meets all quality standards, it is essential to have software in place to help you manage all aspects of the project from start to finish. FTQ360 is a web-based application that provides real-time visibility into every aspect of the project so that any potential issues can be caught and resolved quickly.

FTQ360 software supports all aspects of proactive quality management, including preconstruction document review and approval, project risk assessment with controls integrated into the project QC plan, safety, environmental compliance, punch list items/closeout photographic documentation, subcontractor tracking and evaluation, permissions and access controls, online forms and reports generation, as well as project and organization benchmarking analytics.

Other features of this software include:

-

Real-time data collection via any web-enabled device (smartphone, tablet, or laptop)

-

Project Tracking and Analytics, including Gantt Charts and milestones

-

Quality Control Documentation, including photos/attachments per record captured in the field

-

Exports to Microsoft Excel and PDF formats for easy download and distribution

-

Email alerts and messages for internal communications via the software.

FTQ360 is a robust construction management software that provides real-time visibility into every aspect of the project so that you can resolve any potential problems quickly and easily. Sign up for a free demo, or contact us for more information.